- User-friendly controller

- program up to 250 different die sets or jobs

- Alarm monitoring of critical parameters

- Controls up to 22 outputs

- Stores up to 250 setups/jobs

- Access code prevents tampering

- Saves fluid: precisely controls fluid

Technical Specifications

| Power supply: |

|

| Control inputs: |

|

| Alarm inputs: |

|

| Flow monitor inputs: |

|

| Outputs: |

|

| Valves: |

|

| Alarm relay: |

|

| Maximum input rate: |

|

| Minimum contact open or closed time: |

|

| Alarm inputs: |

|

| Programmable ranges: |

|

| Fuses: |

|

| Operating temperature range: |

|

| Storage temp. range: |

|

| Storage: |

|

| Power: |

|

| Mounting: |

|

Options & Accessories

more

more

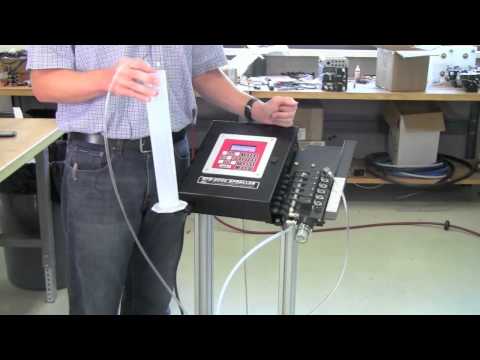

Programmable fluid controller

The SPR-2000™ programmable fluid controller* Controls with electronic precision and consistency how much fluid flows to one or more of these Unist systems: Uni-Roller® S2, TSL™ System, Mini-Roller™, Powered Uni-Roller® and/or Low Volume Spray Nozzles.

Patent No. 6567710*

The automatic lubrication system intermittently actuates a bank of fluid Solenoid Valves (up to 22 outputs) that dispense a programmed quantity of fluid to specific lube points. The valve actuation on this electronic fluid dispenser is determined by production line rates so there is no under or over lubrication whether it is a stamping press or roll forming operation.

Benefits of Automatic Lubrication Systems

- Monitors critical parameters

- Precision fluid control

- Controls up to 22 outputs

- Stores up to 250 different setups/jobs

- Access code prevents tampering

- Saves fluid: precisely controls fluid

Typical SPR-2000™ / Uni-Roller® application

Combine the SPR-2000™ with a Uni-Roller® applicator to reduce fluid usage and save money

On average, a Unist automatic lubrication system can reduce stamping fluid consumption by 50% with some customers reporting reductions as high as 90%!

The SPR-2000™ provides full-featured monitoring of critical parameters such as fluid level, pressure and flow (optional sensors are required) and alerts users with an audible alarm and red LED. An external alarm relay can also be wired directly to a press control on this electronic fluid dispenser.

Access code menu

Access code menu

Provides password-protected access to the system's setting.

Auto setup menu

Auto setup menu

prompts the user for job specifications and automatically creates a new setup (program) for Uni-Roller® applications.

Edit menu

Edit menu

allows the user to modify current setups and program spray nozzles or other auxillary functions.

Alarm menu

Alarm menu

allows the user to monitor critical system functions.

Provides programmable control for the following applications/Unist systems:

- Punching (Mini-Roller™, Uni-Roller® S2)

- Stamping (Mini-Roller™, Uni-Roller® S2, Uni-Roller S2 Powered®, TSL™ System, Low Volume Spray Nozzle)

- Fine blanking (Uni-Roller® S2, Uni-Roller® S2 Powered)

- Deep Drawing (Uni-Roller® S2, Uni-Roller® S2 Powered)

- Application of rust preventives & protective coatings (Low Volume Spray Nozzle, Uni-Roller® S2)

- Fin Stamping (TSL™ System)

- Cupping / Canmaking (Coil Lubrication System™, Sheet Lubrication System™, Tab Stock Lubrication System™)

That's what many of our customers report. By applying the proper amount of fluid, the combination of an SPR-2000™ controller and Uni-Roller® lubricator uses 50 to 90% less lubricant. Plus it decreases the mess, the parts cleaning, fluid recycling and costs associated with in-die spray systems, rag technology and externally lubricated rollers.

MF Minute #5

Learn how to create setups (jobs) in this installment of the Metal Forming Minute

MF Minute #4

John and Mark discuss the importance of adequate stock lubrication.

SPR-2000: Making Electrical Connections

Learn how to make electrical connections to the SPR-2000™ programmable fluid controller.

MF Minute #3

John and Mark discuss the SPR-2000™ programmable fluid controller.

MF Minute #1

In this Metal Forming Minute, John and Mark provide a basic overview of the Uni-Roller® line of stock lubricators.

Perform a Flow Test with SPR-2000

In this how-to video, the process of performing a flow test with an SPR-2000™ programmable fluid controller is demonstrated.