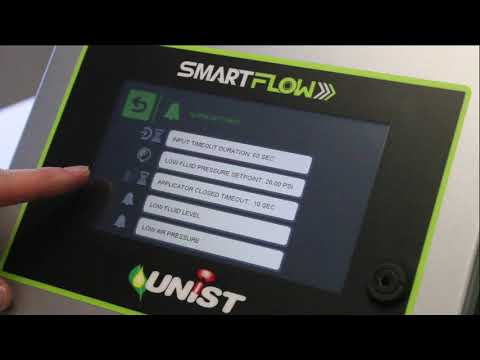

- Touch screen interface

- Easy job creation

- Process monitoring (pressure, flow, valve performance, and line status)

- Fluid tracking - directly measure how much fluid your process is using!

Technical Specifications

| Power supply: |

|

| Cycle inputs: |

|

| Maximum cycle input rate: |

|

| Alarm inputs: |

|

| Outputs: |

|

| Alarm interlock relay: |

|

| Operating temperature range: |

|

| Storage temperature range: |

|

| Press control interface: |

|

| Job storage: |

|

| Job transfer: |

|

Options & Accessories

The SmartFlow® allows metal formers to take full control of die and stock lubrication. This full-featured, programmable fluid controller makes configuring, controlling, monitoring, and tracking fluid application easier than ever, leading to increased profits from the stamping or forming operation.

Designed around an intuitive and easy-to-use operator interface, the SmartFlow® provides simple and guided setup, advanced press control integration, fluid usage tracking, process monitoring, and enhanced diagnostic and maintenance tools.

Save and recall jobs manually or utilize the press control interface for easy, automatic changeover. Back up and transfer jobs and settings between lines with a USB flash drive and the SmartFlow's® USB port. Pair the SmartFlow® controller with Unist's proven line of precision fluid applicators for an intelligent lubrication system that eliminates wasted fluid and mess, reduces scrap, and maximizes profits.

The automatic lubrication system intermittently actuates a bank of fluid Solenoid Valves (up to 22 outputs) that dispense a programmed quantity of fluid to specific lube points. The valve actuation on this electronic fluid dispenser is determined by production line rates so there is no under or over lubrication whether it is a stamping press or roll forming operation.

SmartFlow® Benefits

- Monitors critical parameters

- Precision fluid control

- Controls up to 22 outputs

- Stores up to 250 different setups/jobs

- Access code prevents tampering

- Saves fluid: precisely controls fluid

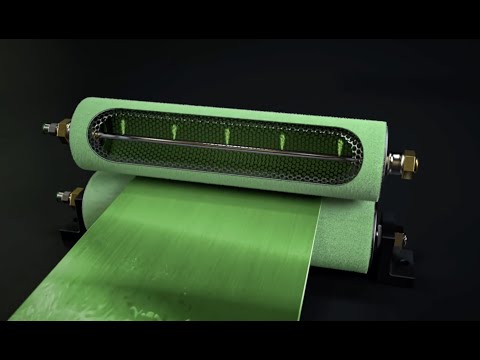

Combine the SmartFlow® with a Uni-Roller® applicator to reduce fluid usage and save money

On average, a Unist automatic lubrication system can reduce stamping fluid consumption by 50% with some customers reporting reductions as high as 90%!

Easily access jobs, settings, maintenance reminders, and more. The intuitive menu allows for easy transition from box to production line

The SmartFlow® controller can monitor pressure, flow, valve performance and line status to ensure lubrication is delivered as required

The job setup wizard guides users through creating a job. Once created, simply increase or decrease the amount of lubricant desired for quick fine tuning of lubricant coatings.

Take the guesswork out of tracking fluid consumption. Directly measure how much fluid your process is consuming with the optional flow meter. With the SmartFlow®, you'll work smarter and know your exact lubricant cost per part

Provides programmable control for the following applications/Unist systems:

- Punching

(Mini-Roller™, Uni-Roller® S2) - Stamping

(Mini-Roller™, Uni-Roller® S2, Uni-Roller S2 Powered®, TSL™ System, Low Volume Spray Nozzle) - Fine blanking

(Uni-Roller® S2, Uni-Roller® S2 Powered)

- Deep Drawing

(Uni-Roller® S2, Uni-Roller® S2 Powered) - Application of rust preventives & protective coatings

(Low Volume Spray Nozzle, Uni-Roller® S2)

SmartFlow® controller and Uni-Roller® lubricator uses 50 to 90% less lubricant. Plus it decreases the mess, the parts cleaning, fluid recycling and costs associated with in-die spray systems, rag technology and externally lubricated rollers.

SmartFlow® Alarms

In addition to precise and measurable lubrication, Unist's SmartFlow® controller features intelligent alarms and warnings to protect downstream equipment and detect issues before they arise.

SmartFlow® Installation Considerations

Before installing your SmartFlow® Controller, there are several considerations to keep in mind. Follow along as we briefly discuss what is necessary for a successful SmartFlow® installation.

Uni-Roller | Internally Fed Lubrication

The Uni-Roller® by Unist ensures even and consistent lubrication for metal forming stock. Replacing flood coolant, the Uni-Roller® can remove the sloppy mess from your operation.

How to Prime Unist Uni-Roller

Follow along as we demonstrate how to prime your Uni-Roller® using a SmartFlow® controller.

Metal Forming | Quick Lubrication Adjustment

Follow along as we show you how to make micro-adjustments to your stock lubrication using the Unist Uni-Roller® with a SmartFlow® controller.

SmartFlow® | Press Control Interface

Metal forming is easier than ever with SmartFlow! Now featuring press control interface, stock lubrication can be controlled directly from your press's controller.

Why SmartFlow

Take complete control of your die and stock lubrication with SmartFlow®. Consistent and accurate fluid application is easier than ever. Interested in enhancing your processes?

Advanced Fluid Tracking

What is advanced fluid tracking? Unlock new levels of precision and control using Unist's SmartFlow® controller. Smartflow® delivers neat and consistent lubrication that protects tooling, tracks and reduces fluid consumption, and more.

Stamping & Metal Forming Lubrication Solutions

An introduction to Unist stock lubrication systems for metal forming

Configuring factory settings on the SmartFlow® controller.

Factory settings are typically set by Unist before shipping a unit to a customer. There may be times when configuring factory settings is necessary such as when the initial application was not known at time of shipping or after a factory reset. This video explains how to configure factory settings on your SmartFlow® controller

Configuring installation settings on the SmartFlow® controller.

Installation settings must be properly set so that the controller is tailored for your application. Watch this video to learn how to access and configure these settings.

Creating a new job on the SmartFlow® controller.

Creating a job on the SmartFlow® is simple and intuitive. Learn how to use the job setup wizard to guide you through creating a new job specific to your application.

Editing an existing job on the SmartFlow® controller.

Making edits to existing jobs is easy with SmartFlow®. Watch this video to learn how to adjust your lubricant settings, nozzle timing, material width, and more.

Editing alarm settings on the SmartFlow® controller

SmartFlow® monitors all critical process parameters. Sometimes, the alarm trigger points need to be adjusted for a specific application. Learn how to properly configure alarm settings in this video.

Monitoring the inputs and outputs on the SmartFlow® Controller

The SmartFlow® allows user to directly view the status of any input or output. This is a useful tool for installation and troubleshooting. Watch this video to learn how to use it.

Performing a flow test on the SmartFlow® controller

Performing a fluid flow test is a critical step when installing the SmartFlow®. Learn how the SmartFlow® makes this process quick and easy.

Running, deleting, and exporting a job on the SmartFlow® controller

The SmartFlow® can save up to 250 jobs. Learn how to run, delete, or export a job to another controller.

Updating firmware on the SmartFlow® controller

Occasionally we may need to update the firmware on the controller with bug fixes or new software features. Watch this video to learn how to update the firmware on your SmartFlow® controller.

Using the SmartFlow® to prime the Uni-Roller® S2

When using a Uni-Roller®, properly priming the rollers is an important start up task. Watch this video to learn how the SmartFlow® walks you through priming rollers.