How do you clean a fluid out of a pump based system?

Typically, a Coolubricator™or Serv-O-Spray™will just run one fluid through it all the time. Occasionally it may be necessary to change fluids used in a system. In that case, the old fluid may need to be removed and/or cleaned from the system to protect against interactions between the old and new fluids, or to keep the new fluid and spray output from contamination from the old fluid.

The degree of cleaning required will depend greatly on the viscosity of the old and new fluids, how critical mixing of the old and new fluids is, and if some residual of the old fluid mixed with the new fluid will affect the operation that the system will be used in.

The viscosity of the old fluid will play a major role in how much disassembly of the system is required. Typically, the thinner the fluid (i.e. lower viscosity) the easier it will be to clean from the system. Fluids that evaporate (alcohols, water, etc.) will also be easier to work with in this instance. For thinner and evaporative fluids, after removing the fluid from the reservoir it may only be required to open the bleed screw on the bottom pump of the stack and allow any remaining fluid in the pump stack to drain.

Once the fluid has been drained from the stack the reservoir cap and bleed screw can be left off for a period of time to allow the residual fluid still inside the pump stack to evaporate. Additionally, the pumps can be cycled to help pump any fluid still left in the internal workings of the pump(s) out. The pumps only need to be cycled until no fluid is observed from the output. Do not cycle the pumps for a long period of time with no fluid in them as it can damage the internal seals in them.

For oil based and higher viscosity fluids, simply draining the pump stack may not be adequate to remove the fluid from the pump stack. In this case, it needs to be determined if mixing the old and new fluids and if dispensing some of the old fluid with the new fluid will adversely affect the operation the system will be used on. If it is determined that mixing the old and new fluids and dispensing some of the old fluid with the new fluid will not lead to any negative effects, then the best course of action would be to drain the reservoir and open the bleed screw on the pump stack and allow as much fluid as possible to drain and then cycle the pumps until no fluid is observed from the output. The reservoir may be removed from the system and cleaned with a soapy water solution, thoroughly rinsed, dried, and reinstalled.

If it is not acceptable to have any residual from the old fluid in the system or mixing the new fluid with the old will yield adverse reactions, then complete disassembly of the pump stack will be required.

Begin by draining and removing the reservoir from the system and thoroughly clean the inside using water and a mild soap solution.

A brush with a long handle may be helpful in cleaning the inside of the 64-ounce reservoir. Once the inside of the reservoir is clean then dry it out. Compressed air may be required to get all the water out of the brass outlet fitting and strainer.

Next, disconnect the fluid outlet connections from the pump. For tips on working with coaxial type tubing reference this video.

On either single line or coaxial output systems, compressed air can be connected to the 1/8” nylon fluid hose(s) and the old fluid can be blown out of the lines.

Next, disconnect any actuation tubing from the pump stack. Shown below is a basic Coolubricator™and Serv-O-Spray™style system. Your system may look different.

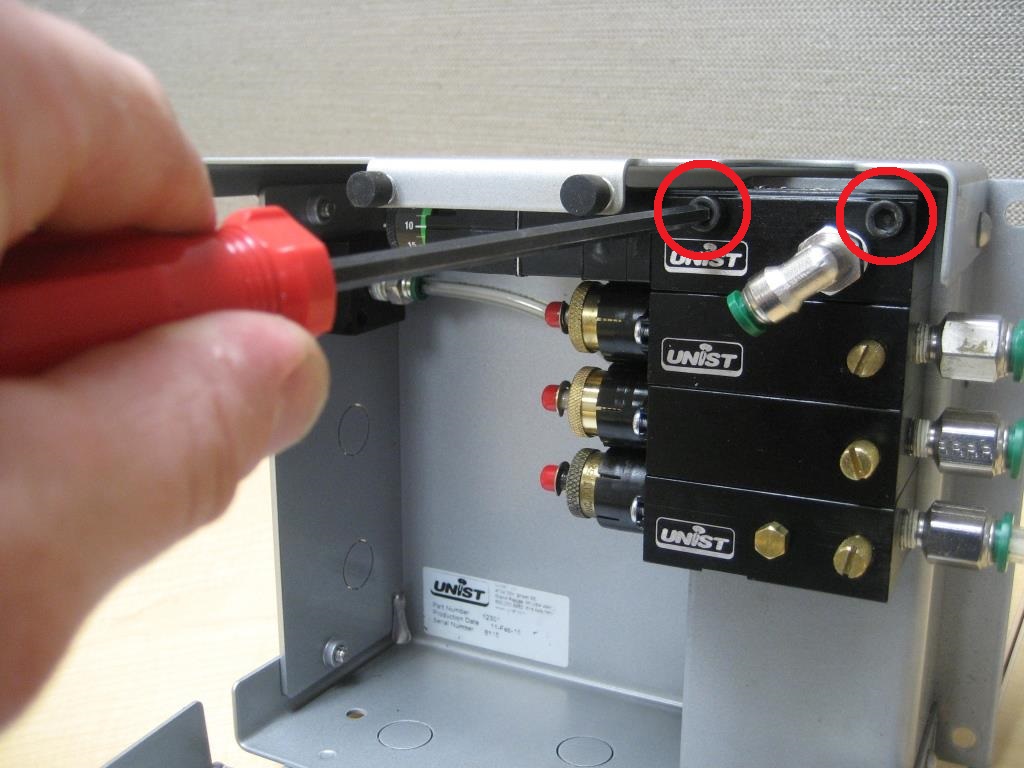

The pump stack can now be unbolted and removed from the enclosure. Note that this pump stack utilizes two screws at the top of the pump stack to attach to the enclosure. Other taller pump stacks may have one or two more screws close to the bottom of the stack to secure it to the enclosure bracket.

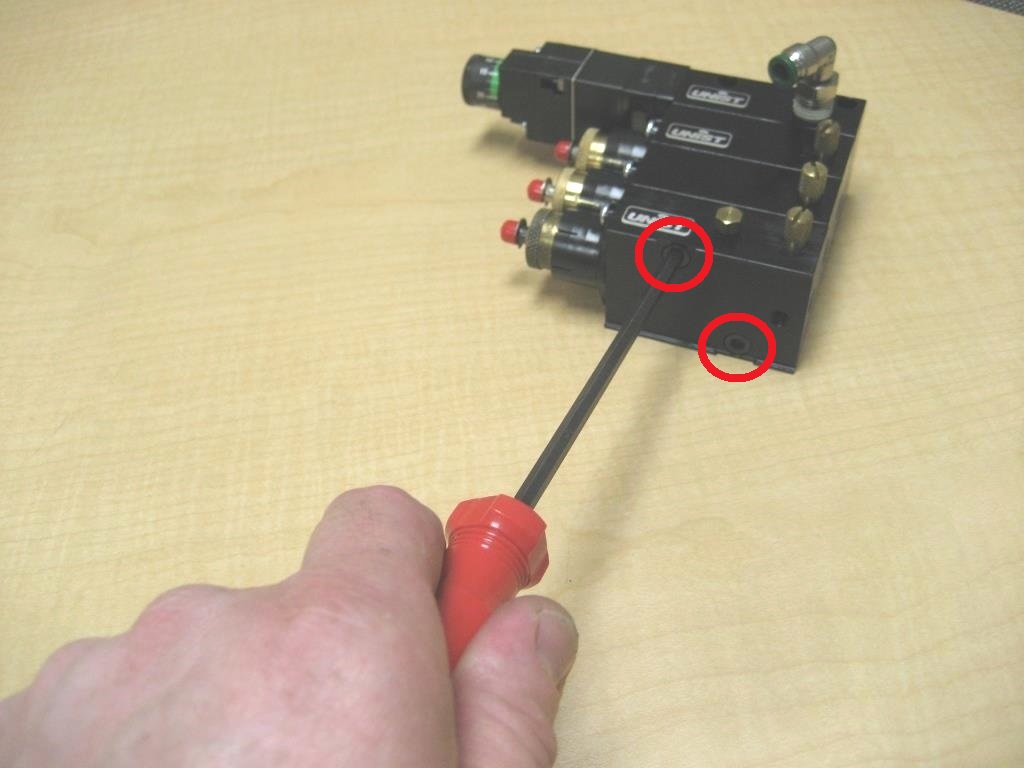

With the pump stack removed from the enclosure the two retaining screws can be removed and the pump stack pulled apart. Note that the pump stack shown uses two socket head cap screws. Taller pump stacks will use a threaded rod with a brass cap nut to retain the stack together.

Once the pump stack has been disassembled, then it will be necessary to clean the fluid port in each manifold block. Each pump will need to be disassembled, cleaned, and reassembled. If the pumps are older, it may be beneficial to rebuild them at this time. For step-by-step information on disassembling and reassembling MV and standard style pumps see the following link.

Once the pumps, manifolds, reservoir, and oil output tubes have been cleaned and reassembled then the entire system can reassembled. After the system has been reassembled then the new fluid can be added to the reservoir. For tips in getting the system back up and running see the following link.