What is the difference between a Coolubricator™ and Serv-O-Spray™ system?

Unist sells both Coolubricator™and a Serv-O-Spray™style fluid spray systems. These systems are typically used in metal cutting operations but can have many different end user applications.

Both systems employ many of the same parts including pumps, enclosures, reservoirs, hoses, and nozzles, but there are a few differences that affect how the systems operate and spray fluid. The biggest difference between the two types of systems is how the pump is actuated and the continuity of the fluid output from the spray nozzle.

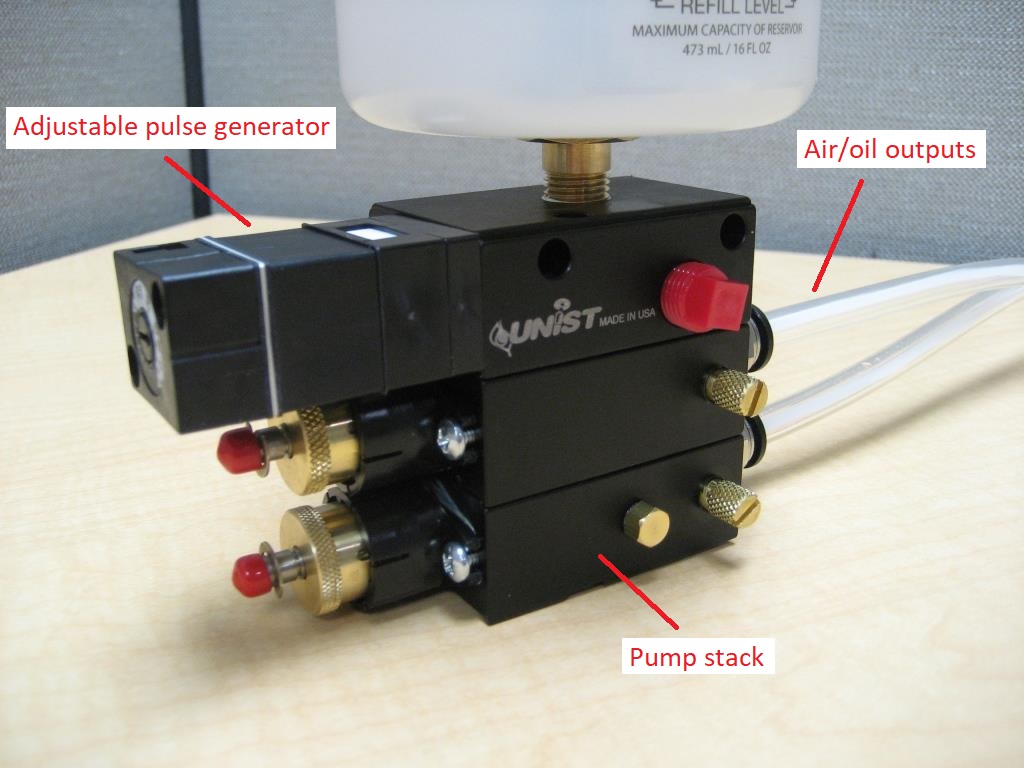

Coolubricators use an adjustable pulse generator to cycle the pump(s). The pump(s) in a Coolubricator™system will continue to cycle at the adjusted rate and the atomizing air (on air/oil systems) will stay on as long as pressurized air is applied to the system. The result is a continuous spray of fluid from the nozzle.

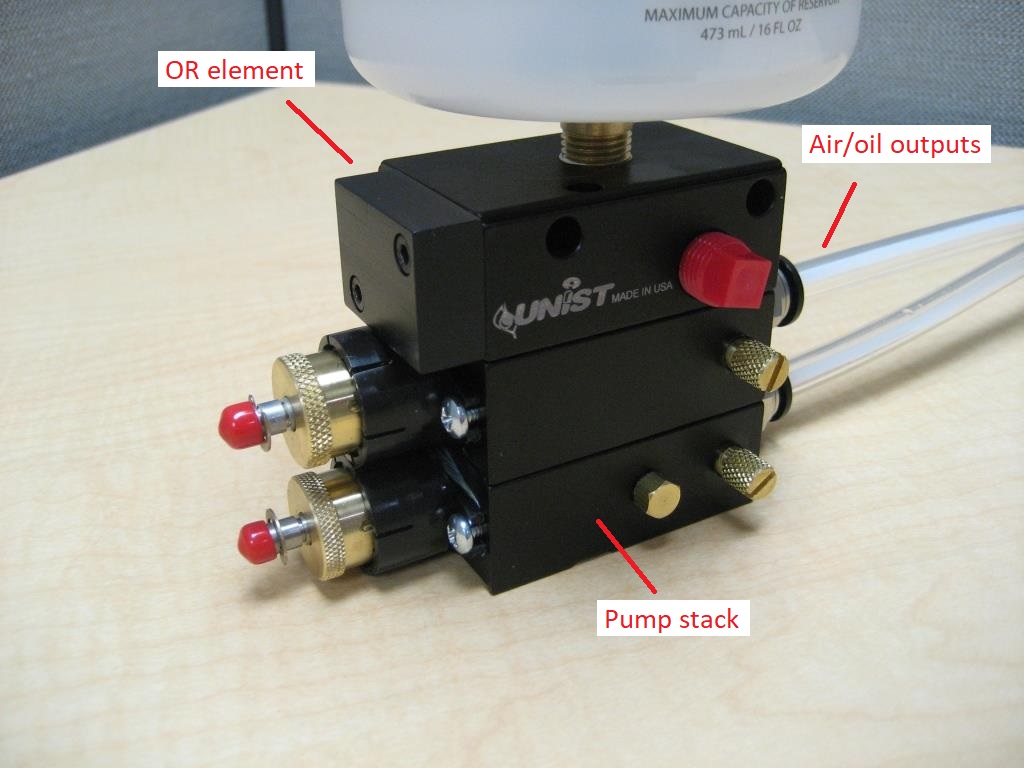

Serv-O-Spray™systems do not have a pulse generator and instead route pressurized air directly to the pump through an OR element to actuate it. The result is that the pump cycles once every time pressurized air is applied and then removed from the system. This gives a quick shot of fluid each time the system is actuated. Like the Coolubricator™ the atomizing air (on air/oil systems) will also stay on as long as pressurized air is applied to the system. The result from this system is a shot of fluid from the nozzle right when the system is actuated.

A Coolubricator™system would work best on an operation that requires continuous lube such as milling, turning, drilling, or sawing operations.

A Serv-O-Spray™system is best suited for operations that just need one shot of fluid per machine cycle or an intermittent quick shot of fluid at a certain time in a cycle. Operations where a Serv-O-Spray™might be advantageous would be a punching or stamping operation, wear point and chain lubrication, and cut-off or shearing operations.