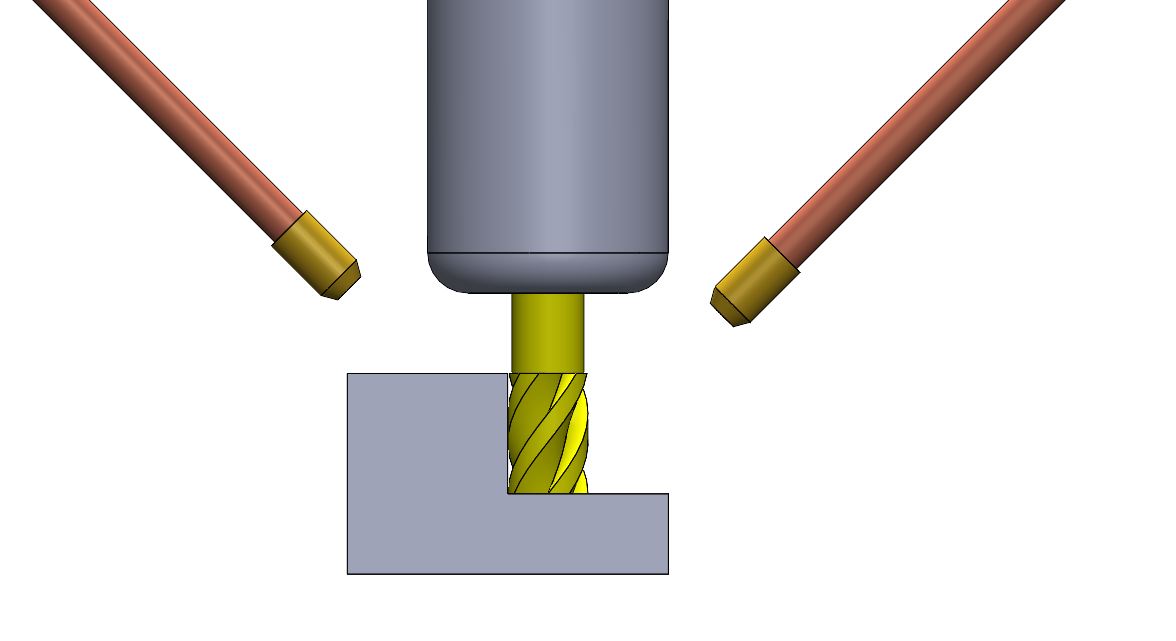

When to use 1 versus 2 spray nozzles.

There are instances when using a Coolubricator™ or Serv-O-Spray™ when it would be beneficial to use two nozzles as opposed to just one for good tool lubrication coverage. For most typical drilling, milling, and turning operations, one nozzle will suffice for proper coverage of the cutting tool. In instances where one nozzle may become shielded from the cutting tool by the work piece or other obstruction it can be helpful to have a second nozzle aimed at the other side of the tool. This can happen when milling deep pockets or if fixturing blocks spray from a nozzle. In the example shown below if the tool is moving right to left, the output from the nozzle on the left is shielded from the cutting tool by the work piece. In this case it would be advantageous to spray from the nozzle on the right to ensure consistent lubrication to the cutting tool.