How do I connect a nozzle to my 230 system?

The 230 Series system uses both single-line and coaxial quick connects.

For single-line applications, simply connect the 1/8” tubing from the nozzle to the push to connect on the manifold outlet.

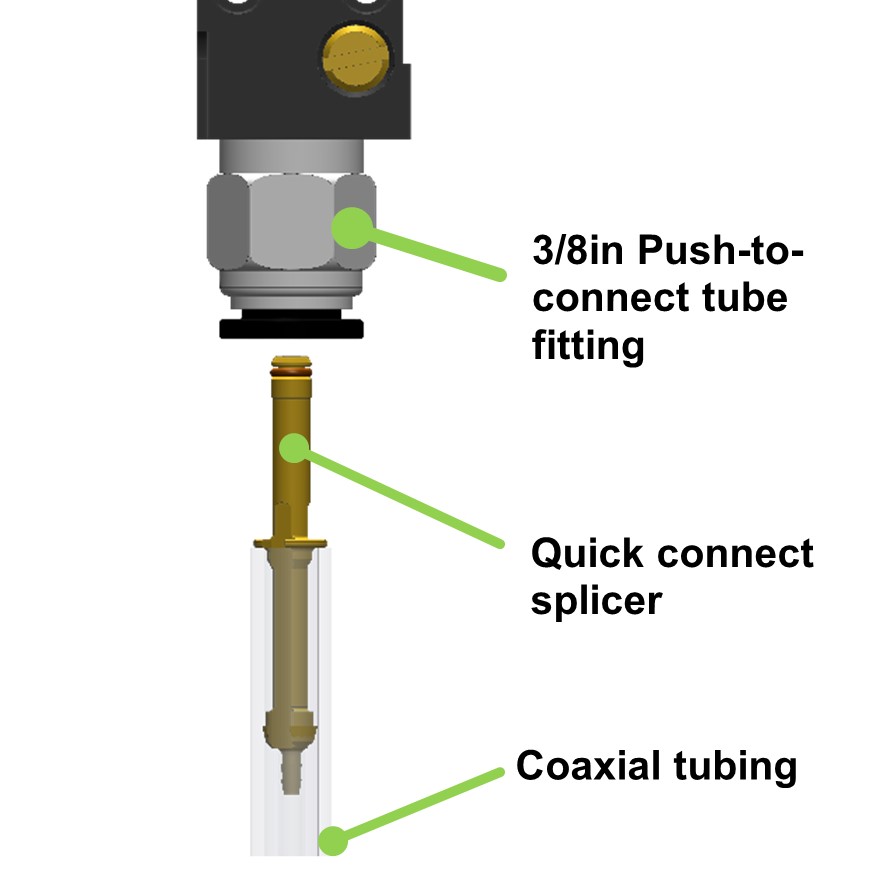

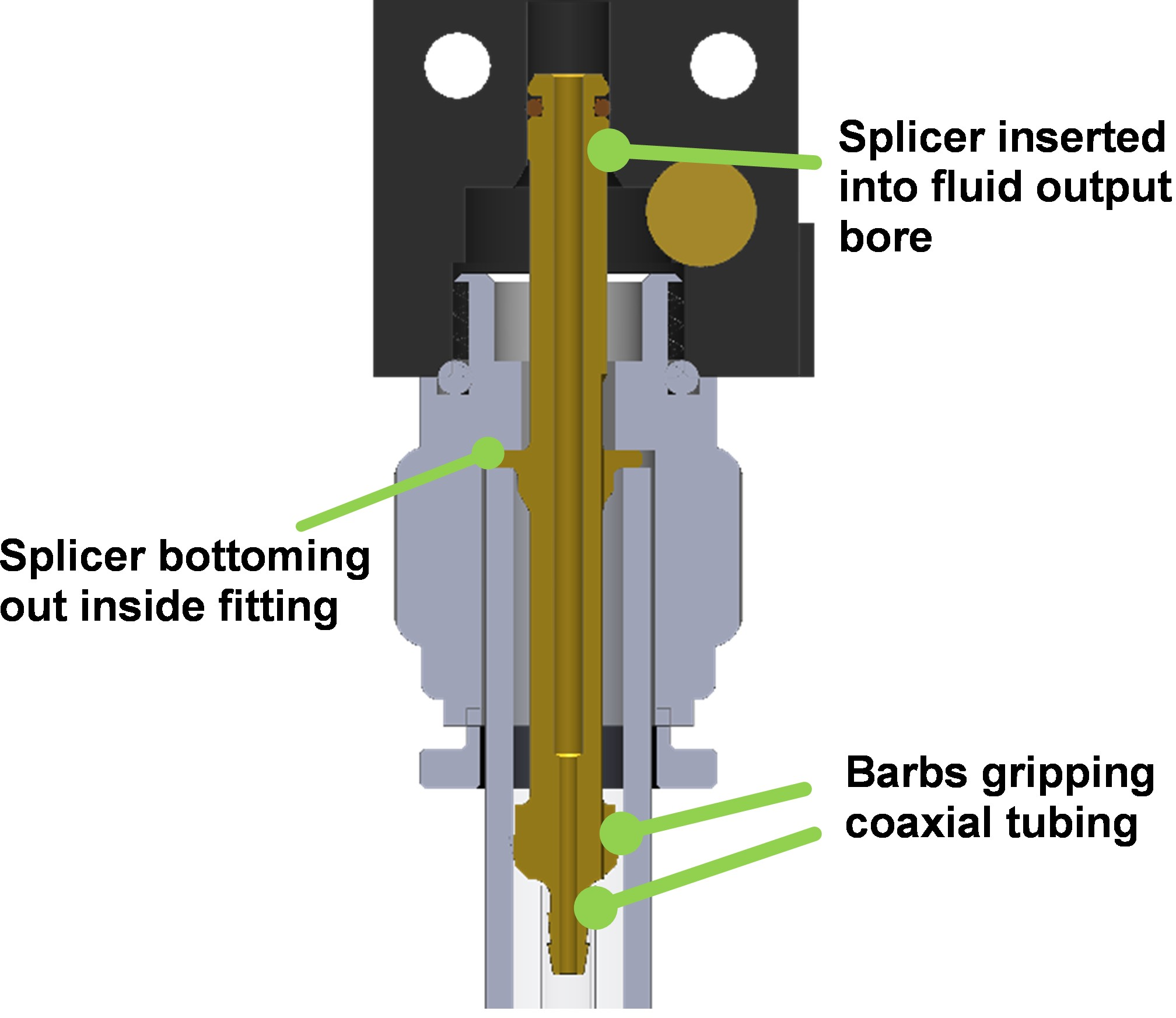

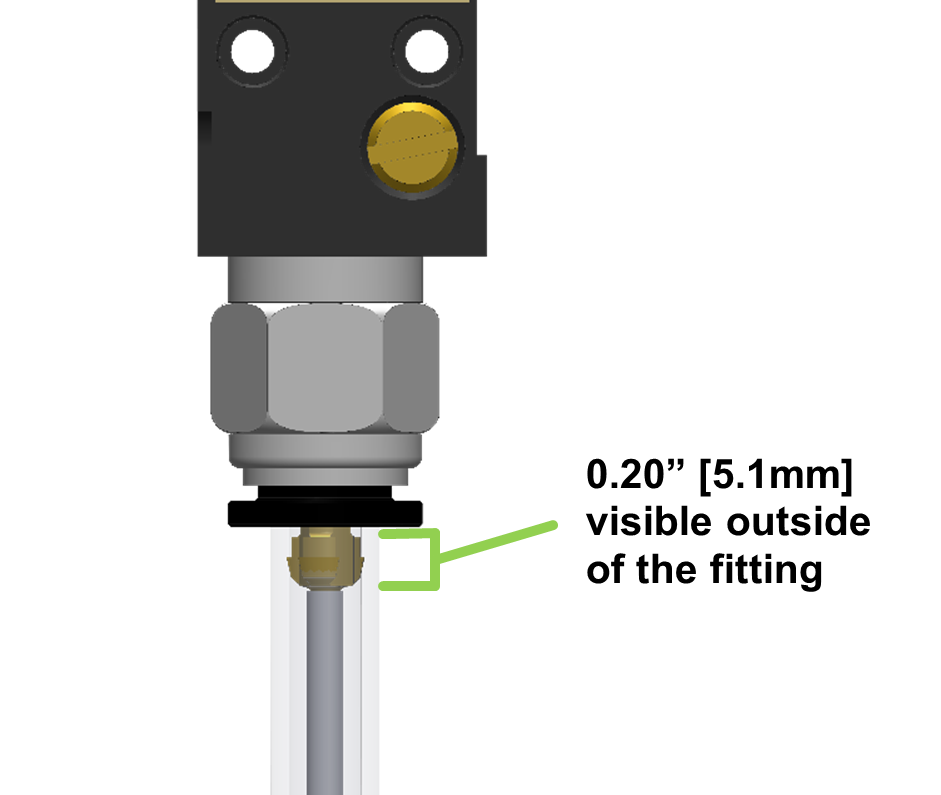

For nozzles with coaxial tubing, fluid passes through the inner tubing, with air in the outer. With the 3/8” push-to-connect fitting threaded onto the manifold at the fluid outlet, simply push the quick connect splicer into the fitting until it is firmly seated. A light coat of grease (Molykote 55 or equivalent recommended) should be applied to the O-ring at the tip of the splicer and a slight twisting motion should be used while inserting to avoid damage to the O-ring upon insertion. You should be able to feel a distinct click when the 3/8” tubing has been captured by the tube fitting. When properly inserted, only about 0.20in [5.1mm] of the quick connect should be visible outside of the fitting. If more of the splicer body can be seen, then there is a risk of fluid leaking into the atomize air of the co-ax tubing.