How do I set up and maintain my air trap?

Unist pump-based spray systems (Coolubricator™ Serv-O-Spray™ etc) can have fluid fed to the pump stack from a pressurized source. An air trap is required to ensure a constant, air-free, supply of fluid to the pump stack.

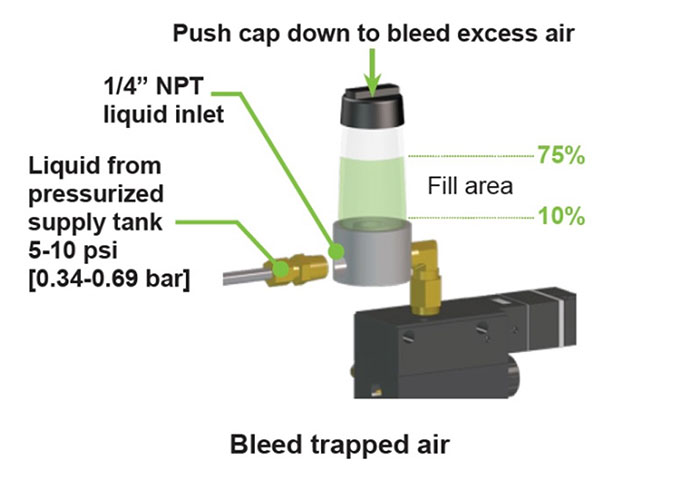

It is recommended that the inlet fluid pressure to the air trap be regulated to 5-10 psi. Excessive pressure going into the air trap can overpower the outlet check valve on the pumps and cause high fluid output and/or fluid leaking from the nozzle(s).

First, connect the fluid supply to the ¼ NPT inlet on the air trap. Once the fluid supply is securely connected it can be pressurized. Next, depress the black cap on the top of the air trap to allow air to exhaust and the fluid to enter. Continue to depress the black cap until the air trap is approximately 75% filled with fluid and then release it.

As the system runs the air trap will require minimal maintenance to ensure proper operation. The fluid level in the air trap may gradually decrease over time. It will be necessary to occasionally depress the black cap on the top of the air trap to bleed air that has built up and restore the fluid level to approximately 75%.