Low-level switch does not change state.

If your low-level switch is not tripped before the reservoir or tank is out of fluid, here are a few things you can check:

- Is the switch wired correctly?

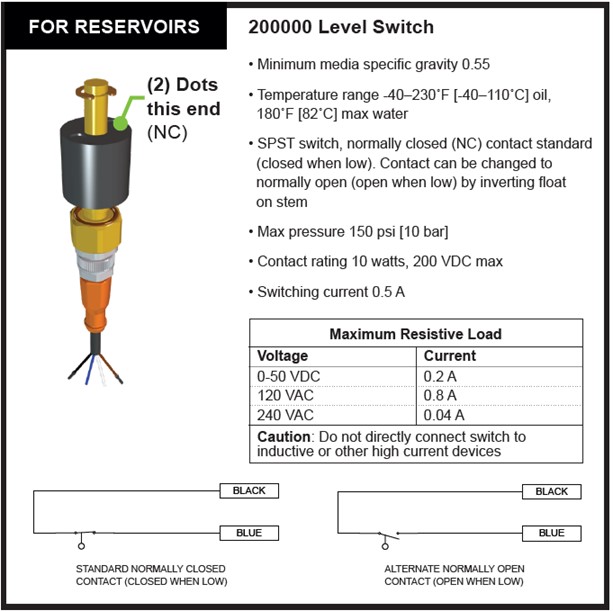

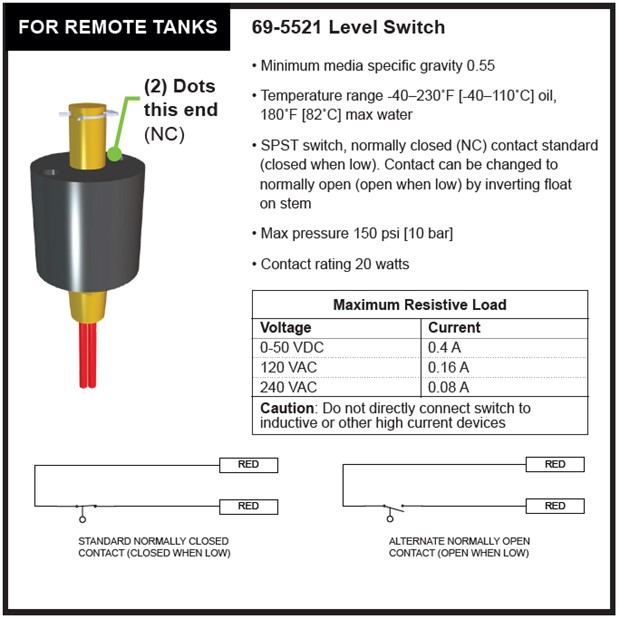

If using a reservoir, the sensor cable will have 4 wires. Only the blue and black wires are used to complete the circuit when a low-level condition occurs. Make sure these are connected to the correct terminals (refer to image below). If using a remote tank, there will be two red wires. Make sure these are connected to the correct terminals (refer to image below).

- Is the switch in the proper orientation?

There are two dots on one end of the float. If you need the contact to close when fluid is low, make sure the two dots are facing up. If you need the contact to open when the fluid is low, make sure the two dots are facing down.

- Did the float fall off the brass body (of the low-level switch assembly)?

If so, make sure the two dots on the float are facing up (for a normally closed contact) and place the float back on the brass switch assembly. In most cases, the float will need to be retained by an e-clip. If this e-clip is not in the tank, contact Unist to purchase the clip.

If the low-level switch is set up correctly, test for continuity between the blue and black wires when the float is oriented with the two dots facing up and is positioned at the bottom of its range of travel on the brass body. If the contact does not close, the internal switch is bad, and the low-level assembly will need to be replaced. Contact Unist for a replacement assembly.