Unist Home | Technical Knowledge Base | | Machining & Cutting | Troubleshooting | No fluid coming from pump.

No fluid coming from pump.

2021-02-16

By Kevin

Initial Troubleshooting Information:

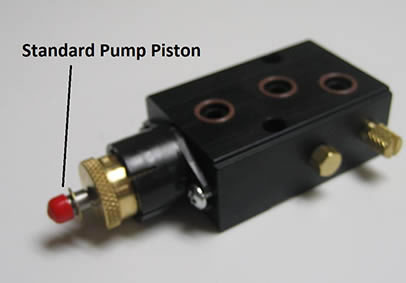

- General Operation: The Unist metering pump is a pneumatically operated positive displacement pump. It requires an adequate air pressure source to properly operate the pump. Pumps can be driven by a pulse generator (PG) which cycles the pump at an adjustable rate as long as air pressure is applied to the system, or an OR element that strokes the pump once every time air pressure is applied to the system. There are two style pumps: Standard and MV. The two style pumps look different, but operate on very similar principles.

- Air Pressure: The pumps need a minimum of 60 psi to operate properly. 80-100 psi is preferred. Less than 60 psi supply pressure to the pumps may affect cycle rate (pulse generator driven pumps), the pump’s ability to stroke, and/or how quickly the pump can be cycled. Reduced air pressure can also reduce air output at the nozzle tip.

- Fluid Pressure: Most pump based systems are gravity fed from a reservoir at atmospheric pressure. If a system is fed from a pressurized tank it should have an air trap on the top of the pump stack. The air trap requires occasional maintenance to ensure proper fluid level. Pressurized fluid fed to a pump stack should typically be set at 5-10 psi. Fluid pressure should never exceed 10 psi.

No fluid output from the pump can be caused by many different things. It is important to establish if the basic requirements for proper pump operation exist. These include proper air pressure supplied to the system (minimum 60 psi), there is fluid supplied to the pump, and the pump is being commanded to cycle. Follow the troubleshooting flow chart below to determine the root cause.