Unist Home | Technical Knowledge Base | | Machining & Cutting | Troubleshooting | Pumps are not stroking.

Pumps are not stroking.

2021-03-11

By Kevin

Initial Troubleshooting Information

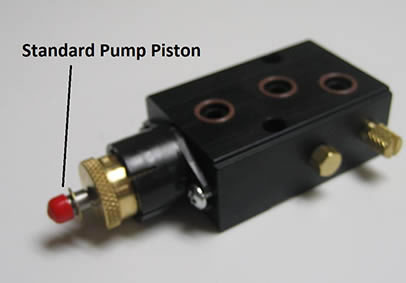

- General Operation: The Unist metering pump is a pneumatically operated positive displacement pump. It requires an adequate air pressure source to properly operate the pump. Pumps can be driven by a pulse generator (PG) which cycles the pump at an adjustable rate as long as air pressure is applied to the system, or an OR element that strokes the pump once every time air pressure is applied to the system. There are two style pumps: Standard and MV. The two style pumps look different, but operate on very similar principles.

- Air Pressure: The pumps need a minimum of 60 psi to operate properly. 80-100 psi is preferred. Less than 60 psi supply pressure to the pumps may affect cycle rate (pulse generator driven pumps), the pump’s ability to stroke, and/or how quickly the pump can be cycled. Reduced air pressure can also reduce air output at the nozzle tip.

A pump that is stuck and/or not stroking can be caused by an inadequate air signal to the pump or an internal problem with the pump. If the pump piston is not moving it is helpful to distinguish if the piston is stopped in the in or out position. Both pumps below are shown in the out position. When the pump receives the proper air signal (either repetitive via a pulse generator or a lone signal on a Serv-O-Spray™) the piston will stroke and will move into the adjustment knob. When the air signal is removed the piston will retract.

Follow the troubleshooting flow chart to determine the root cause