There is fluid in the outer coax tubing.

In a typical Unist spray system with coax tubing the fluid and air run separately from the pump to just before or at the tip where they are mixed together. There should not be any fluid in the outer hose carrying the air. Fluid pooling in the outer hose can result in large blasts of fluid from the nozzle and overall inconsistent fluid output.

The most typical causes of fluid in the outer air hose are too little atomizing air flow used to carry the fluid from the nozzle to the cutting tool and improper nozzle orientation. Ideally, the proper amount of atomizing air flow is just enough to propel the fluid to the cutting tool. Settings are dependent on many factors including the length of tubing from the pump to the nozzle, fluid viscosity, and the machining operation. For systems that use a metering screw to regulate atomizing air flow, a good starting point is 1/2 to 3/4 of a turn open from fully closed. Other systems use various regulators and proportional valves to control atomizing air flow and must be adjusted on a case-by-case basis.

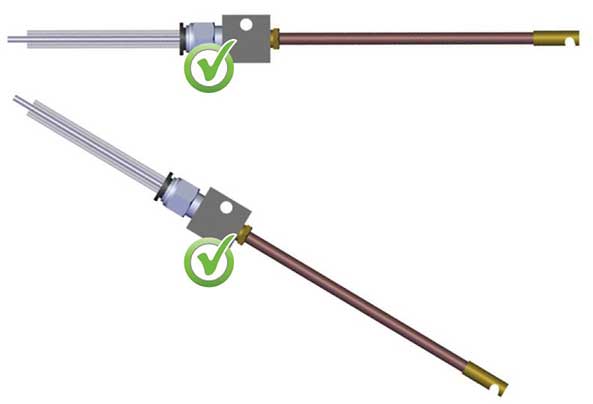

If the nozzle and nozzle coupler block are oriented so they are pointed up this can lead to fluid draining back down the nozzle and nozzle coupler block and pooling in a low spot in the outer air hose.

It is generally best to orient the nozzle and nozzle coupler block horizontally or pointing down so fluid can flow down and eventually out of the nozzle.

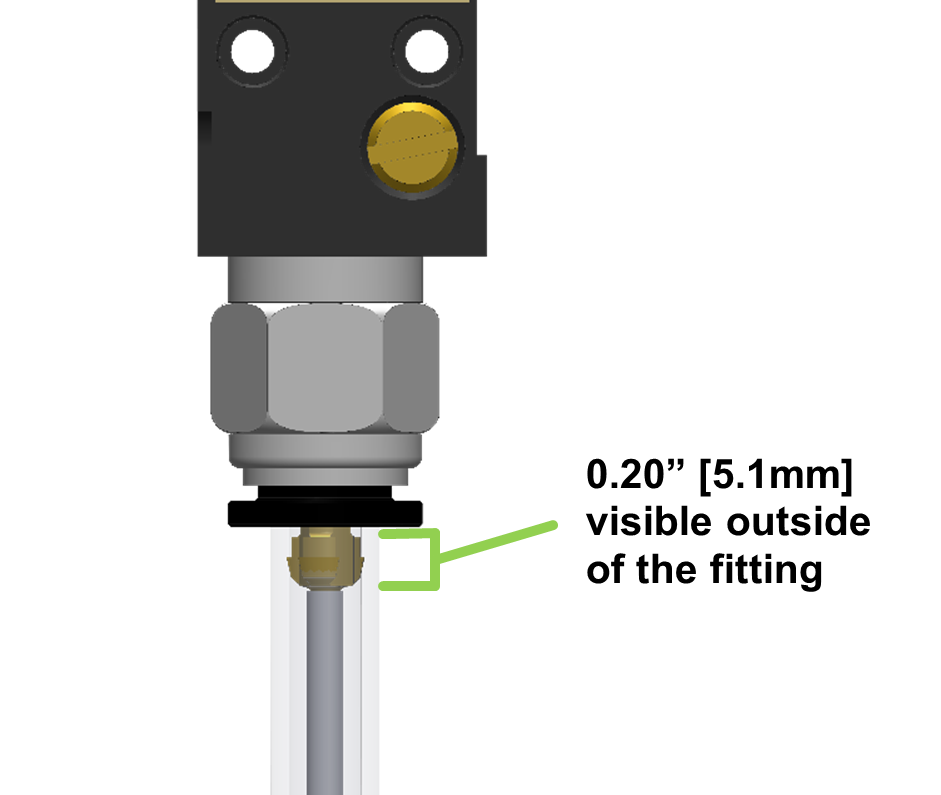

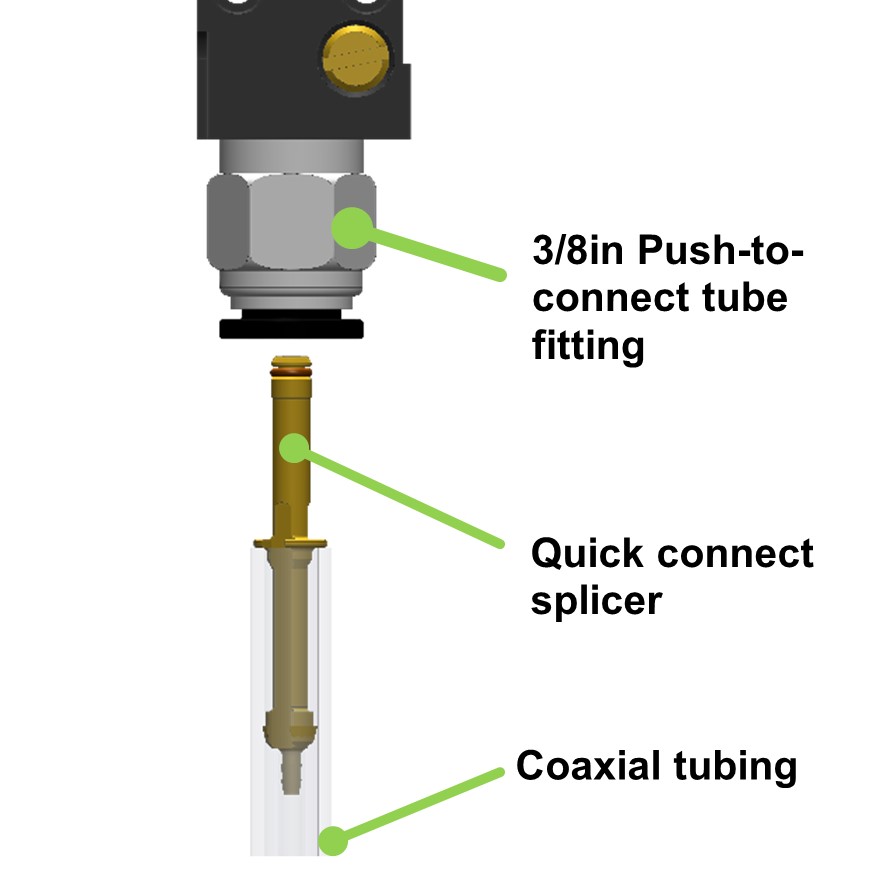

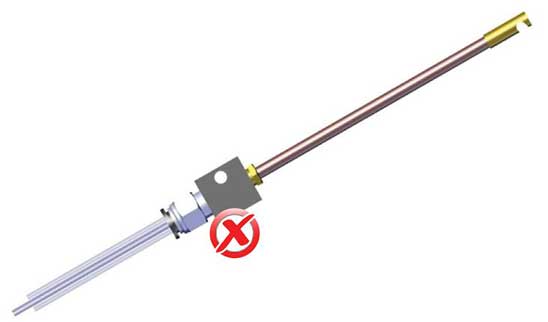

For systems using the quick connect splicer, another common issue that will cause fluid to pool in the outer coax tube is when the quick connect fitting is not installed properly. When properly inserted, only about 0.20in [5.1mm] of the quick connect should be visible outside of the fitting. If this is installed correctly and fluid looks like it is leaking into the outside coax tube from this connection point, the O-ring on the quick connect can be replaced. Contact Unist for a replacement.