- Continuous precision output

- Reliable Unist pump

- Separate air/fluid control

- Economical MQL solution

Technical Specifications

| Outputs: |

|

| Nozzle: |

|

| Pump: |

|

| Reservoir: |

|

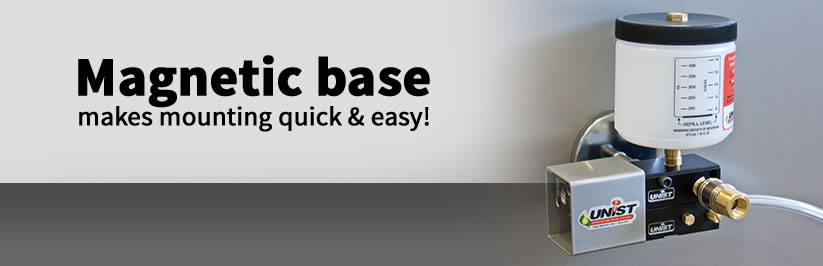

| Mounting: |

|

| Actuation: |

|

- Continuous precision output

- Reliable Unist pump

- Separate air/fluid control

- Economical MQL solution

Provides small shop economy. See how this portable lubricator can lead to big lubricant savings and better quality products. Contact us today.

- Drill presses

- Lathes

- Saws

- Open milling machines

- Boring mills

- Works with metals, woods and plastics

This portable lubricator moves from machine to machine without production delays. Hand-carry this versatile lubricator from one scheduled cutting or machining equipment to the next. A heavy-duty magnet lets you install it with minimal downtime.

This system produces a continuous output of precisely metered lubricants. Air-driven, positive-displacement pumps precisely meter each drop of lubricant at .03 cc/stroke. The 100-million cycle pulse generator allows for automatic, infinite repeat cycling of the metering pump. This ensures that a continuous, external film of lubricant is applied to the tool-work interface.

Lets operator easily control atomization of the spray by adjusting air, pulse per minute and liquid metering.

Adjusts output from 4-200 injection cycles per minute with 0.1 to 3.0 drops of lubricant per cycle. A durable, vented 16 oz. reservoir on the CNC mister holds more than 14,400 drops of lubricant.

Dispenses any highly refined lubricant including Unist’s high-efficiency Coolube{rr} from the oil mist lubrication system's durable, 16 oz. (0.5 L) vented reservoir.

The Coolubricator JR™ combines lubricant and air in a co-axial nozzle tip. The oil mist lubrication system keeps atomization and distribution of the liquid consistent regardless of the hose length. Plastic 12 in. nozzle is coupled with 5 ft. Co-Axial hose. A heavy-duty magnetic base at the hose/nozzle connection of the oil mist lubrication system makes it easier to relocate and position the nozzle at the friction points.

Rebuilding MV Pumps

Learn how to rebuild your MV (Multi-Viscosity) pumps.

Tips & Tricks of Working with Coaxial Tubing

Learn tips for working with coaxial tubing.

Priming A Pump-Based MQL System

In this how-to video, the procedure for priming a pump-based MQL systems is outlined

Working With The Redesigned Capillary Splicer

Learn how to replace nozzles, shorten or replace co-axial hose or retrofit your system to use the improved capillary splicer design.

Testimonial Video - Sigma Machine

Tia Stevenson from Sigma Machine talks about the Quantum™ and Coolube® lubricants.

MQL Minute #7

Unist multi-viscosity (MV) pumps are discussed in this MQL Minute.

Setting Up Your Coolubricator System

Learn how to do initial setup on a Coolubricator™ system.

What is MQL?

An introduction to Minimum Quantity Lubrication (MQL).

Installing Coax Nozzles & Splicer Pins

This video demonstrates how to install co-axial nozzles and splicer pins in a Unist MQL system.

Installing a Uni-Max Pump Rebuild Kit

In this how-to video, the installation procedure for a standard Uni-Max Pump rebuild kit is outlined.

Disconnecting & connecting co-axial hose

This video demonstrates the proper procedure for installing and removing co-axial hose from a Unist MQL (Minimum Quantity Lubrication) system.