Many consider only the purchase price of fluid and fail to realize its hidden costs. Studies have found that once a drum of fluid makes it through your stamping facility, its lifecycle cost can be 8–15 times higher than its initial purchase price!

Runaway stamping fluid’s hidden costs:- Productivity – poorly applied fluid increases scrap

- Downtime – poorly lubricated die components fail early

- Cleanup – cleaning materials & cleaning labor costs

- Wet Parts – affect downstream processes like welding and painting

- Hazards – slips & falls, mist inhalation

- Disposal – excess fluid must be collected and disposed of

Request a Uni-Roller® consultation

By clicking ‘submit’, you are confirming that you have read, understood, and accepted the Unist Privacy Policy.

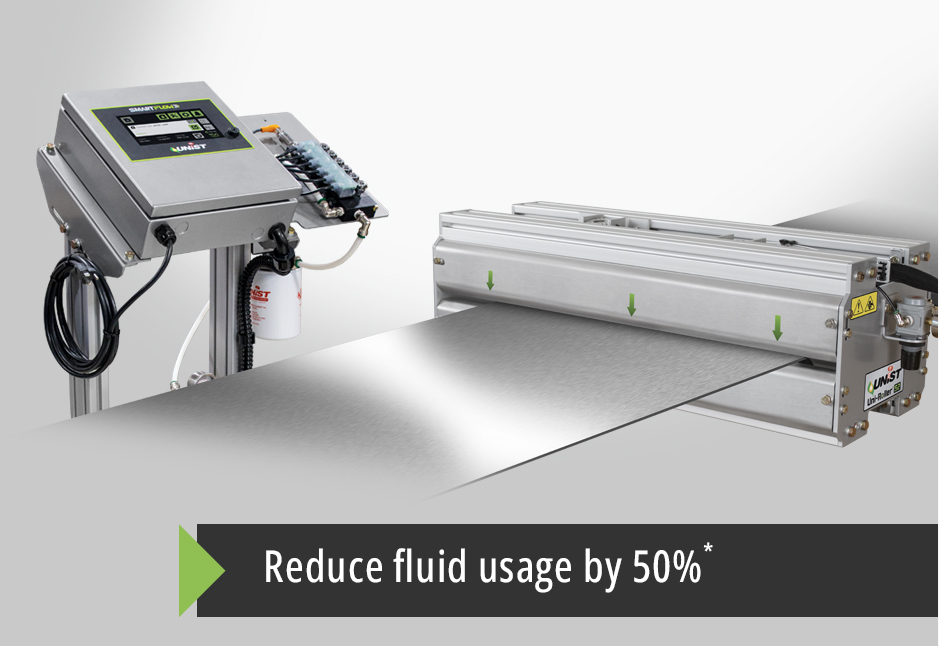

Uni-Roller®

puts fluid on the part being stamped,

not everywhere else!

puts fluid on the part being stamped,

not everywhere else!

Reducing your fluid usage is the best way to combat stamping fluid’s true cost. Uni-Roller® stock lubricators from Unist apply a smooth, uniform coating while significantly reducing fluid usage. In fact, on average, our customers reduce fluid usage by 50% with some reporting a reduction as high as 90%!

*A 50% fluid reduction is average. Your results may vary

Uni-Roller® stock lubricators let you:

- Apply a consistent, predetermined amount of fluid to one or both sides of coil or blank stock

- Apply fluid neatly – no wasted fluid on equipment or floors and no fluid mess

- Create, store, and call up jobs with programmable control

- Keep tabs on the lubrication process with active monitoring and alerts