How does

MQL work?

It does this by delivering lubricant droplets to the cut in the form of an atomized spray. The droplets form a lubricant barrier which is very effective at reducing friction and heat in the cut.

Take advantage of our expertise in Minimum Quantity Lubrication with a FREE, no obligation consultation!

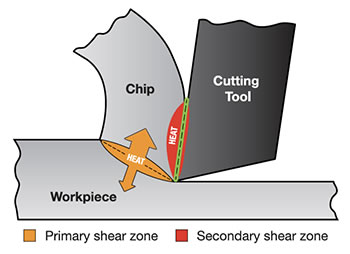

Metal cutting processes generate heat in two zones:

Primary shear zone: shearing action of the material causes heat buildup as the material deforms and eventually flies away as a chip.

Secondary shear zone: The sliding friction between the workpiece and the cutting tool generates heat as the tool plunges into the material.

By applying minute amounts of high-quality lubricant directly to the cutting tool/work piece interface, MQL creates a lubrication boundary which works to reduce the amount of friction and therefore lowers the amount of heat generated in the process. Heat generated by material deformation flows away as the chips break off from the cut. In most MQL configurations, lubricant is carried in an air atomiz ed form to the cutting zone.

An MQL system lets you dial-in the perfect atomized spray

The success of MQL is dependant on its ability to deliver atomized droplets of lubricant into the cutting tool/work piece interface. Because each machining or cutting operation is different in terms of speeds and feeds, cutting tool geometry, and other variables, an MQL system needs to tune the atomized spray to a specific application.

Choosing the right MQL system

Unist MQL systems are the product of over 65 years of experience with MQL. Our systems are built to ensure long term success with Minimum Quantity Lubrication!

See why Unist MQL systems are the choice of manufacturers worldwide!

Next: Unist MQL systems ⤍ Feel like reading more?

Feel like reading more?