Continuous Vs. Intermittent Spray Systems

A major benefit of Precision Fluid Dispensing is the ability to deliver only what is needed. This promotes fluid savings, repeatability and eliminates downstream headaches associated with excess fluid. Manufacturers considering the addition of a precision fluid dispensing system should first evaluate their process and determine if a continuous or intermittent delivery of fluid is required.

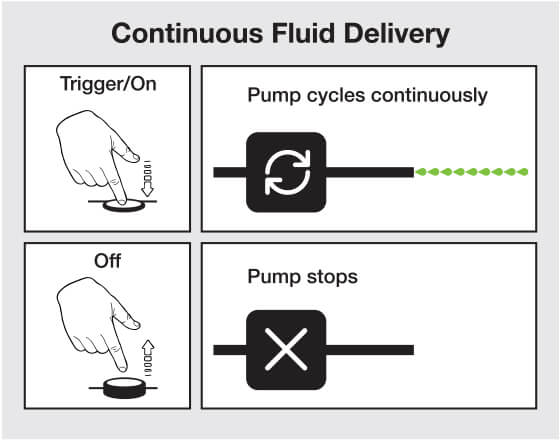

Continuous fluid delivery

A precision fluid dispensing system is continuous if, when actuated, it starts delivering fluid and continues to do so indefinitely until it is stopped.

Example: When the trigger is held on an automatic firearm, it continues to fire repeatedly until stopped by releasing the trigger.

Best for: Processes which run continuously for a given amount of time or which require the constant presence of fluid. I.e. - a lubricant sprayed onto a rotary cutting tool's cutting edges to lubricate them continually as they repeatedly strike the work.

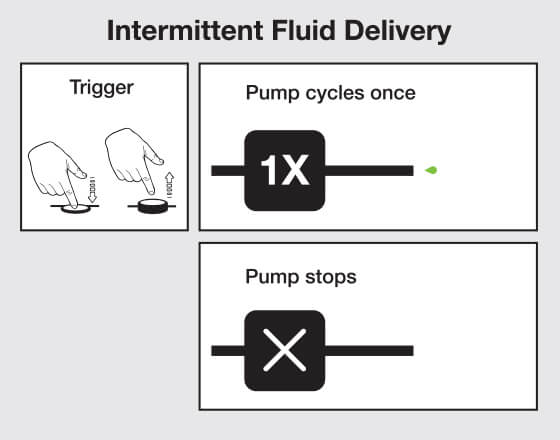

Intermittent fluid delivery

A precision fluid dispensing system is intermittent if, when actuated, it delivers a single "shot" or "burst" of fluid and then stops until it is actuated again – in which case, it will deliver another burst of fluid.

Example: When the trigger is pulled on a semi-automatic firearm, a single round is fired. To fire another shot, the trigger must be pulled again.

Best for: Processes which require an amount of lubricant delivered all at once. I.e. - an assembly process where one part must be coated with a fixed amount of fluid before it is assembled with others.

Why it matters

Not all Precision Fluid Dispensing systems have the capability to deliver fluid in both continuous and intermittent "modes." This is especially true with metered dispensing systems reliant on air-actuated positive-displacement pumps. To keep up with the demands of constant fluid delivery, this type of air-actuated system requires a means to cycle the pump continuously until fluid demand is met. Dispensers that must repeat usually require additional components not present on systems designed to deliver a single-shot. Your best bet is to determine which type of output your application requires then consult the manufacturer to make sure your chosen system will deliver fluid in that manner.