Equipment Maintenance Lubrication

Looking to protect your equipment investment with automatic maintenance lubrication?

Tired of the errors, infrequency, and safety issues that accompany manual lubrication?

- Eliminate the inconsistency of lubricating manually

- Accurate and reliable grease and oil delivery

- Increase safety – automatically lubricate hazardous or restrictive lube points

- Automatically lubricate single or multiple equipment lube points

- Reduce downtime with increased equipment dependability

- Reduce grease and oil consumption and save money

Lubricate equipment friction points such as:

- Gears

- Bearings

- Chain lubrication

- Racks and pinions

- Ball screws

- High speed bearings

- Spindles

- Cables

- Cylinders

Reliable Positive-Displacement Metering

Our metering systems utilize proven positive-displacement metering pumps for repeatable, accurate volumetric dispensing regardless of external temperature or pressure changes. These metering valves/pumps reliably dispense oils between 30 and 5000 SUS and NLGI grade 000 and 00 greases.

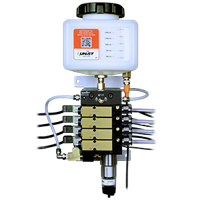

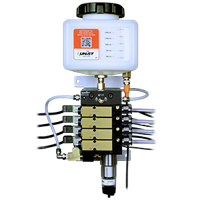

Built to fit your application

Unist automatic lubrication systems feature a modular design and are easily configured to fit your application. Whether you’re dispensing needs are standalone and simple or tightly integrated and complex, Unist has the dispensing technology, and know-how to spec and build your ideal system.

- Build your system with the pumps you require – up to 12 per system

- Activate pumps in groups or individually

- Specify pump type as fluid-only or as air/fluid mixture output

- Mix and match pumps of 3 fixed sizes ( 20µL, 40µL, or 60µL output/stroke) or choose an adjustable output pump

- Activate grease/oil dispenser with discrete or electronic control

- Lubrication monitoring with optional sensors

- Choose 16, 32, or 64oz. integral fluid reservoirs or a remote, pressurized source

- Mount your system conveniently with multiple mounting options

Buy with confidence: Unist service and support

At Unist, we believe our job is far from over after the sale. We are committed to our customers' success and to delivering excellent support. This means readily available parts and expert technical support that is fast and responsive.

How responsive? Chat or call us and talk to a Unist expert immediately during business hours!

Unist business hours: 8AM - 5PM EST MON-FRI

Unist Equipment Maintenance Lubrication Systems: