Videos

Installing a Uni-Max Pump Rebuild Kit

In this how-to video, the installation procedure for a standard Uni-Max Pump rebuild kit is outlined.

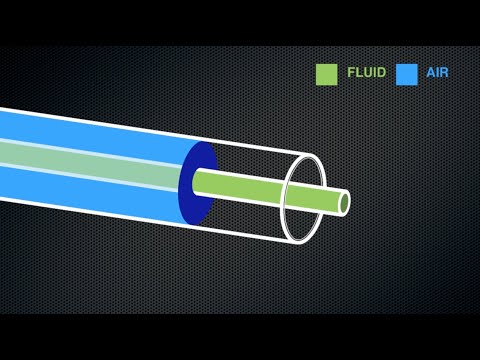

Disconnecting & connecting co-axial hose

This video demonstrates the proper procedure for installing and removing co-axial hose from a Unist MQL (Minimum Quantity Lubrication) system.

Changing Roller Covers (Mini-Roller)

A how-to video explaining how to change roller covers in a Mini-Roller™ stock lubricator.

Changing a Roller Cover (Uni-Roller)

A how-to video explaining how to change roller covers in a Uni-Roller® stock lubricator.

Installing Coax Nozzles & Splicer Pins

This video demonstrates how to install co-axial nozzles and splicer pins in a Unist MQL system.

Rebuild a Uni-Roller Pump Type C

Learn how to rebuild the cam-driven pump in a Uni-Roller® Type C stock lubricator.

Perform a Flow Test with SPR-2000

In this how-to video, the process of performing a flow test with an SPR-2000™ programmable fluid controller is demonstrated.

Powered Roller Cart™ in action

The Powered Roller Cart™ is a mobile lubrication solution for blank/sheet stock.

MF Minute #1 Uni-Roller Systems Overview

In this Metal Forming Minute, John and Mark provide a basic overview of the Uni-Roller® line of stock lubricators.

MQL Minute #2 Coolube Vs Flood Coolant

In this MQL Minute, John and Larry discuss the benefits of Coolube® vs. traditional flood coolant.

MQL Minute #1 MQL Systems Overview

This MQL Minute provides a general overview of Unist MQL (Minimum Quantity Lubrication) systems.

MF Minute #2 Unist Mini-Roller

In this Metal Forming Minute, John and Mark discuss Unist's Mini-Roller™ stock lubricator for narrow coil.

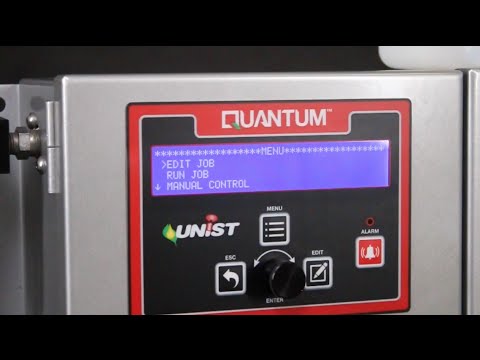

MF Minute #3 SPR-2000 Fluid Controller

John and Mark discuss the SPR-2000™ programmable fluid controller.

MQL Minute #3 Dry Chips With Unist MQL

John and Larry take a look at some dry chips in the Unist shop.

MQL Minute #4 Coolubricator VS Serv-O-Spray

In this MQL Minute, John and Larry discuss the differences between Unist Coolubricator™ and Serv-O-Spray™ systems

SPR-2000: Making Electrical Connections

Learn how to make electrical connections to the SPR-2000™ programmable fluid controller.

MF Minute #4 Adequate Stock Lubrication

John and Mark discuss the importance of adequate stock lubrication.

MQL Minute #5 Bat Nozzle for Sawing

Learn about Unist's specialty BAT nozzle for sawing in this MQL Minute.

MF Minute #5 SPR-2000: Creating Setups

Learn how to create setups (jobs) in this installment of the Metal Forming Minute

MF Minute #6 The New Unist Apex System

Discover the Unist Apex™ System in this Metal Forming Minute.

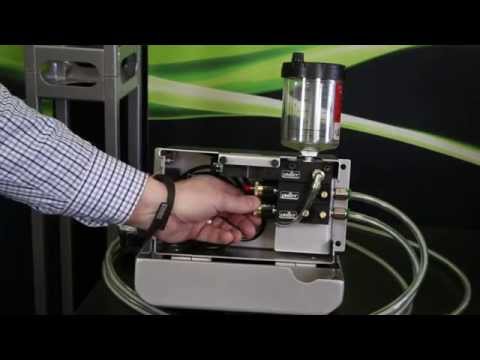

Setting Up Your Coolubricator System

Learn how to do initial setup on a Coolubricator™ system.

MQL Minute #6 Nozzle Positioning for Milling

Learn how to best position your nozzles for milling operations in this MQL Minute.

MF Minute #7 Clearing a low fluid alarm on the SPR-2000

This Metalforming Minute demonstrates how to clear a low-fluid alarm on the SPR-2000™ programmable fluid controller.

MQL Minute #7 Multi-Viscosity Pumps

Unist multi-viscosity (MV) pumps are discussed in this MQL Minute.

Setting Uni-Roller® Pressure Gauge

What pressure should your Uni-Roller® be set to? Follow along as we guide you through setting and adjusting the pressure on your Uni-Roller®.

Allied Machinery lubricates coil with Uni-Roller

Allied Machinery lubricates coil stock with a Unist Uni-Roller lubricator.

Manor Tool - Deep draw with Uni-Roller system

Manor Tool uses an automatic material feed system during the deep drawn stamping process.

Haas gantry router with Unist MQL system

Haas Gantry Router 510 with Unist MQL (Minimum Quantity Lubrication) system

MQL Minute #9 Multiple Outputs

In this MQL Minute, John and Larry discuss Unist MQL systems with multiple outputs.

MF Minute #8 Uni-Roller HG System

Take a look at the new 'HG' option for Uni-Rollers® in this Metal Forming Minute.

Quantum: Calibrating Flow Sensors Quantum: Calibrating Flow Sensors

Learn how to calibrate flow sensors on the Quantum™ system from Unist

Unist Quantum : Advanced lubrication system

The Quantum™ system interfaces directly to machines and their controllers giving you unprecedented control over your MQL application.

Prime and calibrate Revolution System

Learn how to prime and calibrate the Revolution™ system

MQL Minute #10 Dual/Single Channel MQL

Learn the difference between single-channel and dual-channel MQL

Working With The Redesigned Capillary Splicer

Learn how to replace nozzles, shorten or replace co-axial hose or retrofit your system to use the improved capillary splicer design.

Priming A Pump-Based MQL System

In this how-to video, the procedure for priming a pump-based MQL systems is outlined

Changing Roller Covers on a Uni-Roller S2

This video shows how to easily remove the Uni-Roller S2's rollers for maintenance.

Basic Overview: Turning with MQL

This video briefly runs through MQL (Minimum Quantity Lubrication) on CNC Lathes.

Testimonial Video - Grant Industries Customer Grant Industries discusses their Unist Uni-Roller system.

Customer Grant Industries discusses their Unist Uni-Roller system.

Testimonial Video - Sigma Machine Sigma Machine talks about the Unist Quantum™ and Coolube® lubricants.

Tia Stevenson from Sigma Machine talks about the Quantum™ and Coolube® lubricants.

MQL On CNC Lathes Implementing and enjoying the benefits of MQL on a CNC lathe are simple, and worth the investment.

This video briefly runs through MQL (Minimum Quantity Lubrication) on CNC Lathes. Implementing and enjoying the benefits of MQL on a CNC lathe are simple, and worth the investment. Unist has successfully implemented MQL on many lathes performing a variety of operations in a variety of materials. Contact Unist today to learn more about how we can help improve your manufacturing processes through the use of MQL on your CNC lathe.

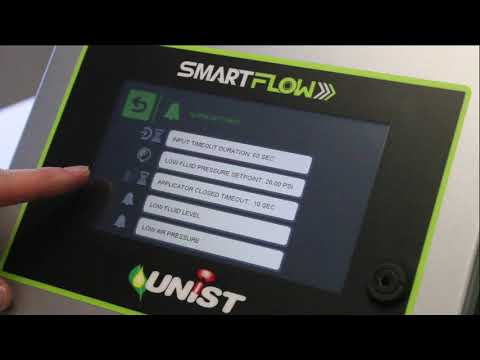

Configuring factory settings on the SmartFlow® controller. This video explains how to configure factory settings on your SmartFlow® controller.

Factory settings are typically set by Unist before shipping a unit to a customer. There may be times when configuring factory settings is necessary such as when the initial application was not known at time of shipping or after a factory reset. This video explains how to configure factory settings on your SmartFlow® controller

Configuring installation settings on the SmartFlow® controller. Learn how to access and configure installation settings.

Installation settings must be properly set so that the controller is tailored for your application. Watch this video to learn how to access and configure these settings.

Creating a new job on the SmartFlow® controller. Creating a new job is a simple and intuitive process with SmartFlow®

Creating a job on the SmartFlow® is simple and intuitive. Learn how to use the job setup wizard to guide you through creating a new job specific to your application.

Editing an existing job on the SmartFlow® controller. Editing an existing job is a simple and intuitive process with SmartFlow®

Making edits to existing jobs is easy with SmartFlow®. Watch this video to learn how to adjust your lubricant settings, nozzle timing, material width, and more.

Editing alarm settings on the SmartFlow® controller Learn how to edit the alarm settings on a SmartFlow® controlller

SmartFlow® monitors all critical process parameters. Sometimes, the alarm trigger points need to be adjusted for a specific application. Learn how to properly configure alarm settings in this video.

Monitoring the inputs and outputs on the SmartFlow® Controller This video shows you how to monitor the inputs and outputs on the SmartFlow® controller.

The SmartFlow® allows user to directly view the status of any input or output. This is a useful tool for installation and troubleshooting. Watch this video to learn how to use it.

Performing a flow test on the SmartFlow® controller This video shows you how to perform a flow test on the SmartFlow® controller.

Performing a fluid flow test is a critical step when installing the SmartFlow®. Learn how the SmartFlow® makes this process quick and easy.

Running, deleting, and exporting a job on the SmartFlow® controller This video shows you how to run, delete, and export a job on the SmartFlow® controller.

The SmartFlow® can save up to 250 jobs. Learn how to run, delete, or export a job to another controller.

Updating firmware on the SmartFlow® controller This video shows you how to update the firmware on the SmartFlow® controller.

Occasionally we may need to update the firmware on the controller with bug fixes or new software features. Watch this video to learn how to update the firmware on your SmartFlow® controller.

Using the SmartFlow® to prime the Uni-Roller® S2 This video shows you how to prime your Uni-Roller® S2 using the SmartFlow® controller.

When using a Uni-Roller®, properly priming the rollers is an important start up task. Watch this video to learn how the SmartFlow® walks you through priming rollers.

Stamping & Metal Forming Lubrication Solutions

An introduction to Unist stock lubrication systems for metal forming

Advanced Fluid Tracking

What is advanced fluid tracking? Unlock new levels of precision and control using Unist's SmartFlow® controller. Smartflow® delivers neat and consistent lubrication that protects tooling, tracks and reduces fluid consumption, and more.

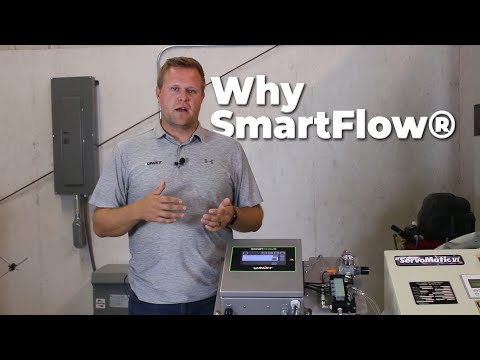

Why SmartFlow

Take complete control of your die and stock lubrication with SmartFlow®. Consistent and accurate fluid application is easier than ever. Interested in enhancing your processes?

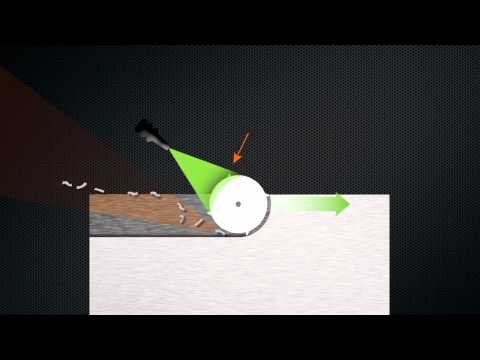

Bandsaw Lubrication System Installation

A Unist saw blade lubrication system can make a huge impact on your saw's performance. Follow along as we discuss the benefits of minimum quantity lubrication, how it works and how it can fit onto your machine.

SmartFlow® | Press Control Interface

Metal forming is easier than ever with SmartFlow! Now featuring press control interface, stock lubrication can be controlled directly from your press's controller.

Metal Forming Spray Nozzles

When additional/supplemental lubrication is needed for metal forming try Unist spray nozzles. Offering multiple mounting options and several spray patterns, our spray nozzles ensure clean and even lubrication.

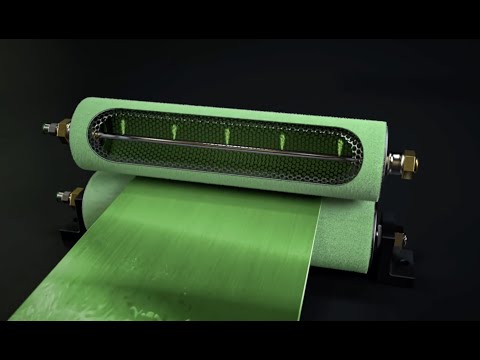

Uni-Roller | Internally Fed Lubrication

The Uni-Roller® by Unist ensures even and consistent lubrication for metal forming stock. Replacing flood coolant, the Uni-Roller® can remove the sloppy mess from your operation.

How to Prime Unist Uni-Roller

Follow along as we demonstrate how to prime your Uni-Roller® using a SmartFlow® controller.

Metal Forming | Quick Lubrication Adjustment

Follow along as we show you how to make micro-adjustments to your stock lubrication using the Unist Uni-Roller® with a SmartFlow® controller.

SmartFlow® Alarms

In addition to precise and measurable lubrication, Unist's SmartFlow® controller features intelligent alarms and warnings to protect downstream equipment and detect issues before they arise.

SmartFlow® Installation Considerations

Before installing your SmartFlow® Controller, there are several considerations to keep in mind. Follow along as we briefly discuss what is necessary for a successful SmartFlow® installation.

How to Install Pulse R™ | Instructions

Step by step instructions how to install a Pulse R™ pump onto your Unist Coolubricator™, Serv-O-Spray™, or Saw Blade Lube System™.

How to Replace Your Pulse Generator

Follow along as we show you how to replace the pulse generator on your Unist system.