Unist Precision Fluid Dispensing Systems seamlessly integrate into production or assembly lines for automatic, precise fluid dispensing. Built for demanding industrial environments, they reliably dispense oils, coolants, greases, and other fluids, enhancing operational efficiency through neat, accurate dispensing and fluid usage reduction.

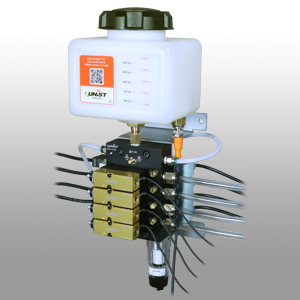

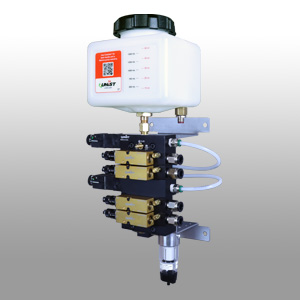

230 Micro Pump™ Systems - Modular, positive-displacement pump-based systems

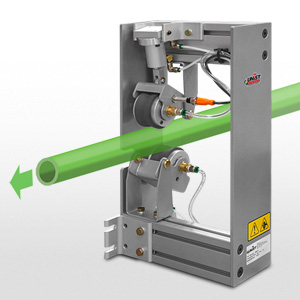

Engineered Systems - Pump or pressure based systems engineered for unique applications

Unist has been advancing manufacturing with precision fluid dispensing systems for over 60 years. Our expertise enables us to tailor the ideal fluid dispenser for each application, including custom solutions for unique challenges. Our dedication to quality and exceptional service has fostered partnerships across diverse sectors, including automotive, aerospace, furniture, electronics, and space exploration.

230 Micro Pump™ systems deliver fluid accurately with microliter precision for demanding dispensing scenarios. With modular components and plenty of options, each system is built-to-suit, guaranteeing it complements new and existing production lines.

- Continuous or intermittent fluid output

- Choose up to 12 separate fluid outputs

- Fluid-only or Fluid/Air mixture outputs available

- Control pumps individually or in groups

- Precise output regardless of temperature change

- Save money by reducing fluid usage

- Automatic wear-point lubrication

- Assembly lubrication

- Application of industrial coatings

- Fluid delivery on OEM equipment

Unist’s engineers design custom pump or pressure-based systems tailored to your unique application and specific goals..

- End-of-arm/robotic fluid delivery/spraying

- Automated rust inhibitor/coating application

- Time-based automated wear-point lubrication

- Coating of wire, rod, tube, or other round profiles

- Die-casting lubricant/process fluid application

- Automated cleaning applications

- End-of-arm cutting tool lubrication

- Conveyor lubrication

- Glue activator spraying application

- Application of mold release agents