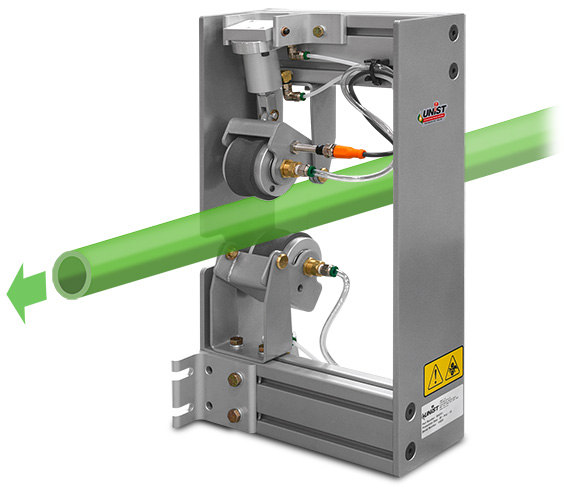

- Internally-supplied roller

- Durable aluminum & steel construction

- Pneumatic cylinders keep rollers engaged with material

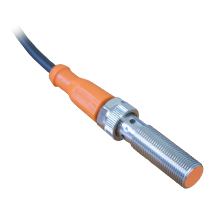

- Rotational input sensor for consistent coating as line speed changes

Technical Specifications

| Stock type: |

|

| Max. stock diameter: |

|

| Min. stock diameter: |

|

| Fluid type(s): |

|

| Fluid supply: |

|

| Applicator material: |

|

| Controller: |

|

| Power: |

|

| Mounting: |

|

Options & Accessories

more

Round Stock Lubrication Solution

The Unist [product name] is your solution for coating or lubricating round-profile material such as cable, tubing, wire, or pipe. Combined with a SmartFlow® programmable fluid controller and fluid supply, the [product name] will consistently apply the correct amount of fluid to round profiles between 0.1" and 1.5" in diameter (2.54 – 38.1 mm) without the waste or mess caused by excess application.

- Consistent fluid application

- Neat application - No excess fluid mess

- Reduces fluid usage - Saves money

- Easily integrated with your line

[product name] applications:

Lubricate or coat round-profile material between 0.1" and 1.5" (2.54mm – 83.1mm) including:

- Wire

- Cable

- Pipe / Tubing

- Round stock

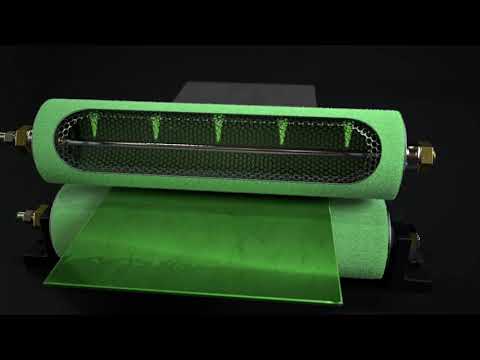

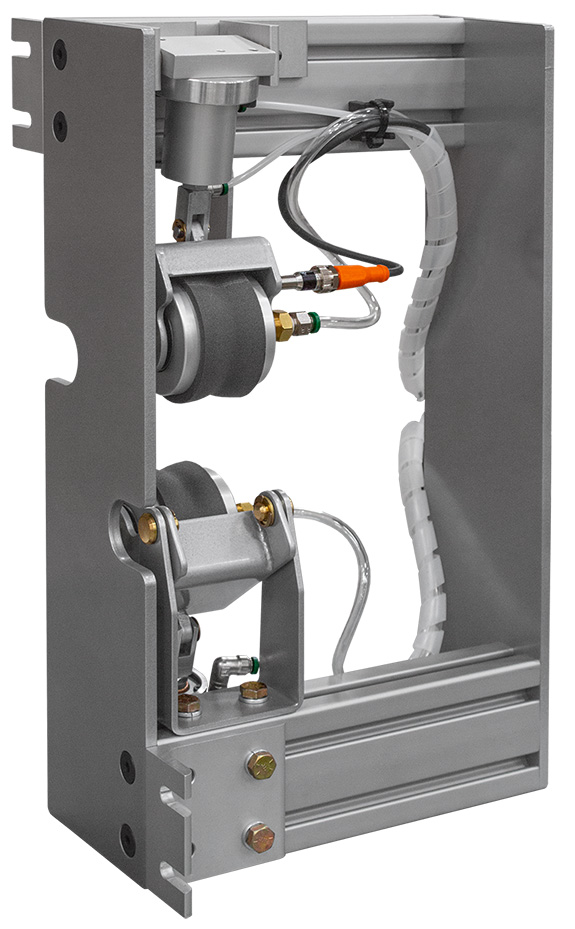

The internally-supplied difference

The internally-supplied rollers are essential to precisely applying the fluid. Inside each of the rollers is a dispenser tube with small holes placed along its length. Fluid is injected into the dispenser tubes from the fluid controller and dispensed across the inside of the rollers.

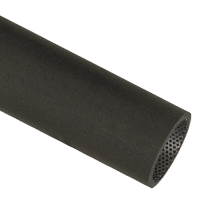

The lubricant is transferred to the stock through durable polyurethane foam roller covers. These cover materials apply lubricant smoothly and evenly across the entire circumference of round-profile material.

The [product name]™ applies the exact amount of lubricant required. This eliminates the mess and waste associated with spray application systems and externally lubricated roller systems. The result is not only a cleaner shop, but also significant savings from decreased fluid waste, improved die life, better part quality and increased machine up-time. Many customers have reported savings resulting in a return on investment of less than six months!

Construction

The [product name] is constructed from a rugged powder-coated steel frame and durable steel and anodized aluminum components to perform for years in demanding industrial applications. Powerful pneumatic cylinders ensure that rollers maintain contact with the material at line speeds up to 500ft/min. (152m/min.). The [product name] is easily mounted to vertical or horizontal surfaces using included brackets ( mounting bolts/hardware not included ).

Need parts?Should your [product name] require service, Unist has the knowledge and part availability to help get you running again quickly and easily.

Delivers return on investment in less than 6 months

That's what many of our customers report. By applying the proper amount of fluid, the [product name] uses 50 to 90% less lubricant and decreases the mess, parts cleaning, fluid recycling and costs associated with spray systems and externally lubricated rollers.

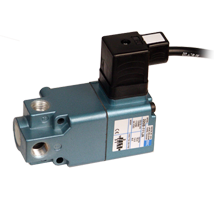

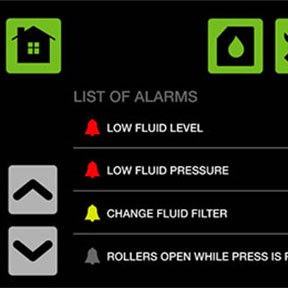

Take control with the SmartFlow®

The SmartFlow® alerts you to issues before they become expensive problems that interrupt or stop your production lines. With the SmartFlow® you'll know immediately if the fluid supply runs low, if fluid pressure varies, or if flow to the applicator is interrupted (Level, pressure, and flow sensors required). The SmartFlow® features an intuitive, easy-to-use interface as well as an access code to prevent unauthorized tampering or changes in fluid settings.

- Monitors critical parameters

- Controls up to 22 outputs

- Stores up to 250 setups

Easy to use touch screen interface.

The SmartFlow® controller can monitor pressure, flow, valve performance and line status.

Job setup wizard makes job creation easy.