- Up to 3 separate mix ratios

- Accurate flow control

- Maintain the perfect pressure & mix

- Easy setup & intuitive interface

- Continuous monitoring

Technical Specifications

| Water supply requirements: |

|

| Power requirements: |

|

| Holding tank capacity: |

|

| Mix ratio range: |

|

| Number of mix ratios: |

|

| Mixed fluid supply: |

|

| Mixed fluid pressure: |

|

| Tote stand size: |

|

Options & Accessories

Accurate & repeatable fluid mixing

The Uni-Blend™ System is designed to accurately mix water with concentrated fluids in any ratio from 1:1 to 50:1 and deliver the mixture under pressure to a customer-supplied piping network. The Uni-Blend™ System automatically mixes batches and maintains a reserve supply of up to 50 gallons per ratio. Up to three batches of differing ratios can be maintained in separate tanks. The Uni-Blend™ System is the only fully programmable industrial fluid mixing system available on the market and is built for years of service in tough, industrial environments.

- Up to 3 separate mix ratios

- Accurate flow control

- Maintain the perfect pressure & mix

- Easy setup & intuitive interface

- Continuous monitoring

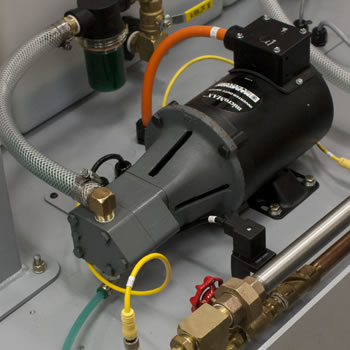

The Uni-Blend™ System utilizes precise flow meters to ensure accurate mixing. Mixing is controlled by the PLC which opens a water valve and monitors the water flow rate. Simultaneously, the PLC controls the rotational speed of a gear pump which delivers concentrate at the proper rate for the programmed mix ratio. The flow rates are constantly monitored to maintain the proper rate regardless of viscosity, temperature, or downstream pressure. This level of precision allows the Uni-Blend™ System to deliver the perfect batch each and every time.

The Uni-Blend™ System is designed to constantly circulate your fluid to maintain a homogeneous mixture. The mixed fluid in the tank is stored at atmospheric pressure and delivered to your piping network under pump pressure. To ensure continuous circulation, the piping network should be configured as a loop starting and returning to the Uni-Blend™ System. To set and maintain proper fluid pressure, a relief valve is installed in the return line of the loop.

At the heart of its advanced control system is an industrial PLC and touch screen user interface which makes monitoring the operation and setting mix ratios easy.

The fluid mixing equipment is designed to constantly monitor the mixing operation and create an alarm condition if a fault occurs. The system features a warning light as well as an alarm output on the PLC which can be used for remote monitoring of the fluid mixing equipment.

The Uni-Blend™ System maintains a continuous supply by monitoring fluid levels and automatically replenishing your batch when necessary. The holding tank(s) contains a level sensor that is monitored by the PLC. The tank will fill with the mixture until it reaches the appropriate level for the programmed batch size, at which time the water valve will close and the concentrate pump will stop. This process will repeat itself as necessary to refill the tank when the fluid drops to a pre-programmed level.

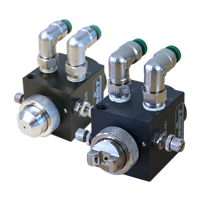

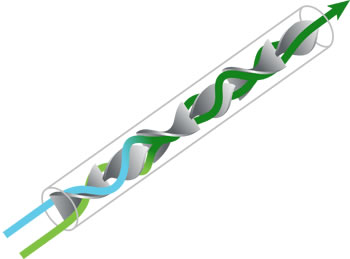

The Uni-Blend™ System utilizes an in-line static mixer to ensure a complete blend of the water and concentrate. The design of the static mixer’s internal fins force the water and concentrate to intermix. This results in a perfect homogenous mixture from the fluid mixing equipment.

MF Minute #9

An introduction to the Uni-Blend™ fluid mixing system.