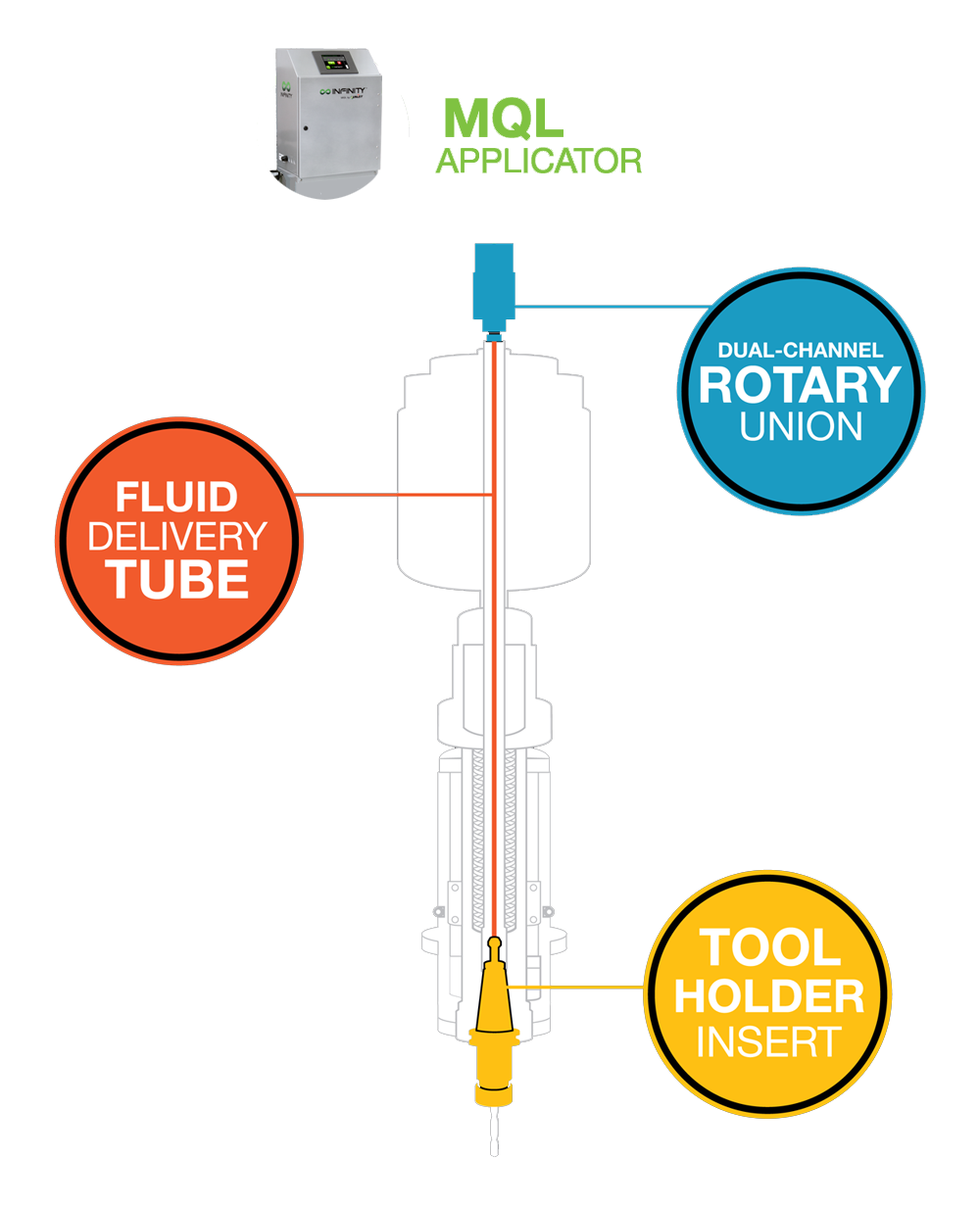

Through-Spindle MQL

Through-spindle MQL is the most consistent, clean, and seamless way to apply MQL in a CNC machine and offers many benefits. With proper tool design, lubricant is delivered precisely where needed; even when cutting holes or slots. This allows every tool in the machine to be individually optimized. Unlike with external nozzles, there is no spraying from a distance. Users have found this reduces the amount of MQL fluid needed up to 70% when compared with external nozzles!

Components

Interested in converting your machine and experiencing the benefits of through-spindle MQL in your process? Unist has the ideal MQL system and all the components to make your switch successful.

What you'll need:

1.) Unist MQL System/Applicator

1.) Unist MQL System/Applicatorcapable of through-spindle delivery

2.) Unist Spindle Kit

2.) Unist Spindle Kit(consists of a specialized rotary union & fluid delivery tube)

3.) MQL Tool Holder Kit

3.) MQL Tool Holder Kitfits into most common CAT and BT style tool holders