- Digitally-controlled output tracks fluid usage

- Integrates with the controller on your machine

- Consistent output at all flow rates

- Nearly unlimited programmable MQL rates

- Active monitoring to ensure optimal performance

Technical Specifications

| MQL outputs: |

|

| Unist Spindle Kit available: |

|

| Fluid delivery: |

|

| Programmable MQL rates: |

|

| Reservoir size: |

|

| Pump output: |

|

| Low fluid level sensor: |

|

| 1 outlet control enclosure dimensions: |

|

| 2 outlet control enclosure dimensions: |

|

| Fluid enclosure dimensions: |

|

Options & Accessories

more

more

Unparalleled Precision

The Infinity™ uses patent-pending pump technology to deliver fluid accurately and repeatably, even at very low flow rates. It delivers continuous flow rates from 5-500 mL/hour, is not sensitive to fluid viscosity or temperature, and eliminates the need for output calibration. This technology simplifies the overall system, eliminating fluid heaters and complex valves often associated with other approaches.

The Infinity™ gives you direct, digital control of air and fluid flow rates. This provides a nearly unlimited number of air/fluid combinations for use in any operation. The Infinity’s™ precision and accuracy make process control simple and effective, and its reliability makes it a shop favorite.

Active monitoring of spindle back pressure, fluid flow rates, fluid tank levels, and other important operational parameters ensure the system is performing well. In the rare case that an issue does arise, detailed tracking of the system behaviors make troubleshooting fast and precise.

The Infinity™ can be integrated with the machine controller to give complete and seamless control from the operator interface or an optional touch screen interface is available to give operators an easy and intuitive interface at the unit itself.

Less is more

The Infinity’s™ positive-displacement pump technology results in a much simpler system than those based on other technologies. This reduction in complexity has a direct relationship to the reliability and maintainability of the system. The elimination of fluid heaters and complex valves that are required for a time-based flow MQL system means there are fewer parts to maintain. Furthermore, the elimination of output calibration saves not only the time and effort, but an entire class of errors related to a bad calibration.

Easy Integration

A robust set of control parameters are available in the Infinity™ controller which allows a full and complete integration with the machine controller and access to all of the advanced capabilities of the Infinity™. A compatibility interface for controllers that may already have interfaces for other MQL applicators is also supported. This compatibility interface gives basic control of the unit with minimal integration effort.

MQL Minute #10

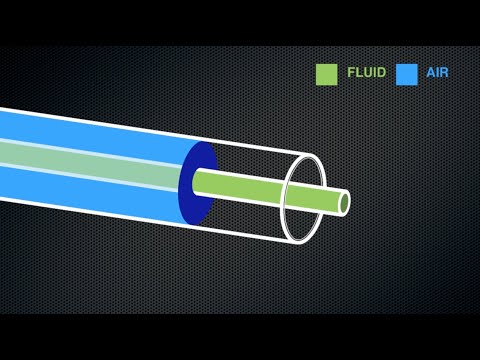

Learn the difference between single-channel and dual-channel MQL

Testimonial Video - Sigma Machine

Tia Stevenson from Sigma Machine talks about the Quantum™ and Coolube® lubricants.

What is MQL?

An introduction to Minimum Quantity Lubrication (MQL).

MQL Minute #3

John and Larry take a look at some dry chips in the Unist shop.