- Reduce lubricant consumption by 50% or more

- Quick-change rollers for easy maintenance

- Cleaner floors & work areas

Technical Specifications

| Stock type: |

|

| Stock thickness: |

|

| Stock width: |

|

| Fluid type(s): |

|

| Fluid supply: |

|

| Applicator material: |

|

| Controller: | |

| Power: |

|

| Mounting: |

|

| Air: |

|

Options & Accessories

more

more

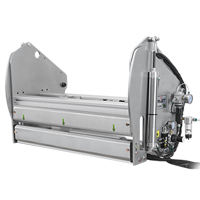

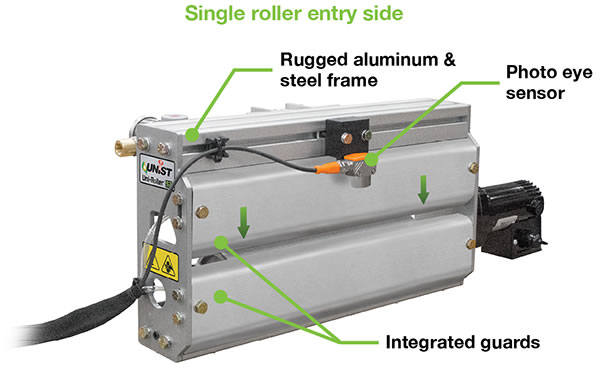

The Uni-Roller® S2 Powered is the ultimate solution in blank stock lubrication. Combined with a SmartFlow® programmable fluid controller, the S2 Powered will apply the correct amount of fluid for your application and do it consistently from one blank to the next.

- Reduce lubricant consumption by 50% or more

- Cleaner floors & work area

- Quick-change rollers for easy maintenance

Uni-Roller® S2 Powered applications:

- Punching

- Stamping

- Fine blanking

- Deep drawing

- Application of rust preventives and other protective coatings

Delivers return on investment in less than 6 months

That's what many of our customers report. By applying the proper amount of fluid, the Uni-Roller® S2 Powered lubricator uses 50 to 90% less lubricant for stock lubrication. Plus it decreases the mess, the parts cleaning, fluid recycling and costs associated with in-die spray systems, rag technology and externally lubricated rollers.

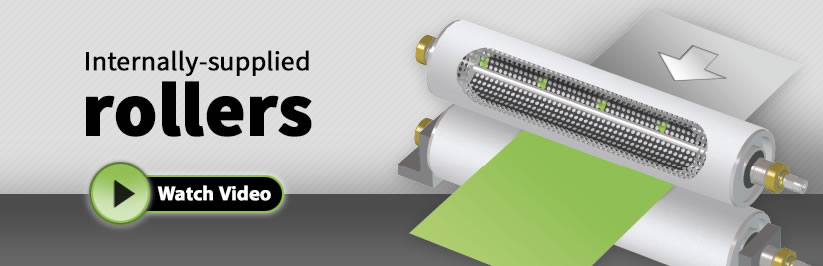

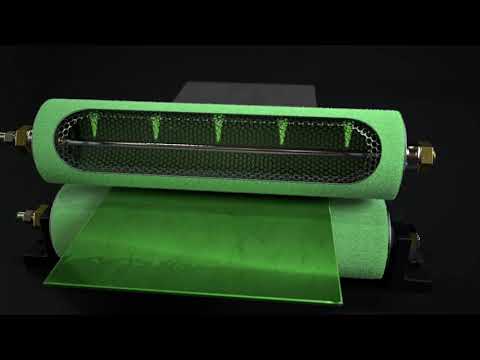

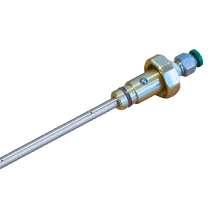

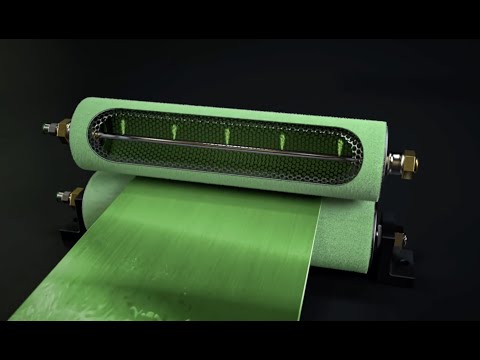

The internally-supplied rollers are essential to precisely applying the fluid. Inside each of the rollers is a dispenser tube with small holes placed along its length. Fluid is injected into the dispenser tubes from the fluid controller and dispensed across the inside of the rollers.

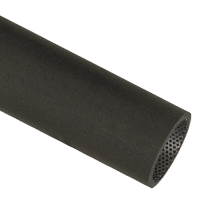

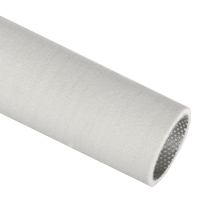

The lubricant is transferred to the stock through durable polyester felt or polyurethane foam roller covers. These cover materials apply the lubricant smoothly and evenly across both the top and bottom of the stock.

The Uni-Roller® S2 Powered applies the exact amount of lubricant required. This eliminates the mess and waste associated with in-die spray systems and externally lubricated roller systems. The result is not only a cleaner shop, but also significant savings from decreased fluid waste, improved die life, better part quality and increased machine up-time. Many customers have reported savings resulting in a return on investment of less than six months!

Uni-Roller® systems deliver smooth and consistent lubrication.

The brushed stainless steel guards protect the rollers and guide material when loading coil stock or feeding blanks. With the guards removed for better access, a roller can be changed in about a minute using a single wrench. The Uni-Roller® S2 Powered is built to handle any manufacturing environment without sacrificing ease of maintenance.

A single roller set is used for widths of 18” [457.2 mm] or less where the lower roller is directly driven. For blanks over 18” [457.2 mm] wide, multiple 12” [304.8 mm] wide roller sets are staggered and overlapped. Each lower roller is driven by a heavy-duty chain from a central shaft.

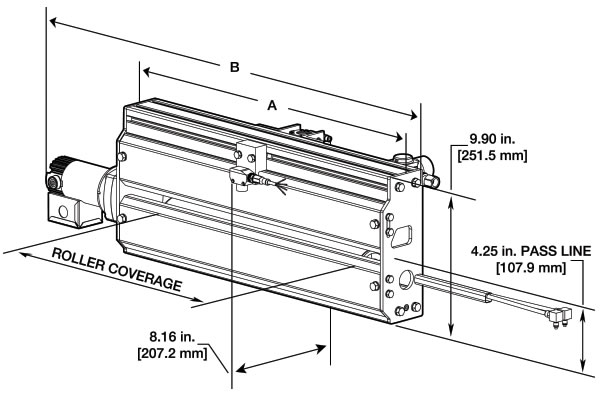

| Roller coverage | A (extrusion length) | B (overall width) |

|---|---|---|

| 3” [76.2 mm] | 12” [304.8 mm] | 14.24” [361.7 mm] |

| 6” [152.4 mm] | 12” [304.8 mm] | 20.24” [514.1 mm] |

| 12” [304.8 mm] | 18” [457.2 mm] | 26.24” [666.5 mm] |

| 18” [457.2 mm] | 24” [609.6 mm] | 32.24” [818.9 mm] |

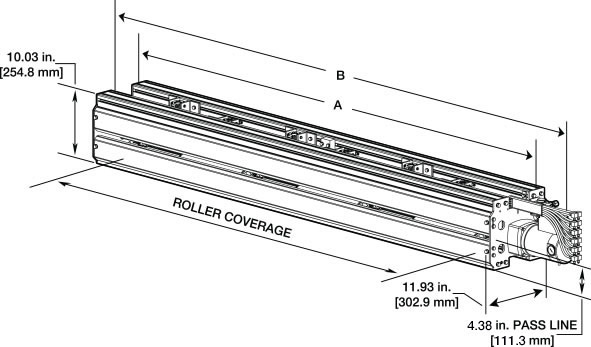

| Roller coverage | A (extrusion length) | B (overall width) |

|---|---|---|

| 23” [596.9 mm] | 30” [762 mm] | 41.18” [1046.0 mm] |

| 35” [596.9 mm] | 42” [1066.8 mm] | 53.18” [1350.8 mm] |

| 46.5” [1181.1 mm] | 54” [1371.6 mm] | 65.18” [1655.6 mm] |

| 58” [1473.2 mm] | 66” [1676.4 mm] | 77.18” [1960.4 mm] |

| 69.5” [1765.3 mm] | 78” [1981.2 mm] | 89.18” [2265.2 mm] |

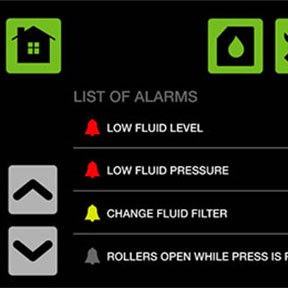

Take control with the SmartFlow®

The SmartFlow® alerts you to issues before they become expensive problems that interrupt or stop your production lines. With the SmartFlow® you'll know immediately if the fluid supply runs low, if fluid pressure varies, or if flow to the applicator is interrupted (Level, pressure, and flow sensors required). The SmartFlow® features an intuitive, easy-to-use interface as well as an access code to prevent unauthorized tampering or changes in fluid settings.

- Monitors critical parameters

- Controls up to 22 outputs

- Stores up to 250 setups

Easy to use touch screen interface.

The SmartFlow® controller can monitor pressure, flow, valve performance and line status.

Job setup wizard makes job creation easy.

Uni-Roller | Internally Fed Lubrication

The Uni-Roller® by Unist ensures even and consistent lubrication for metal forming stock. Replacing flood coolant, the Uni-Roller® can remove the sloppy mess from your operation.

How to Prime Unist Uni-Roller

Follow along as we demonstrate how to prime your Uni-Roller® using a SmartFlow® controller.

Metal Forming | Quick Lubrication Adjustment

Follow along as we show you how to make micro-adjustments to your stock lubrication using the Unist Uni-Roller® with a SmartFlow® controller.

SmartFlow® | Press Control Interface

Metal forming is easier than ever with SmartFlow! Now featuring press control interface, stock lubrication can be controlled directly from your press's controller.

Stamping & Metal Forming Lubrication Solutions

An introduction to Unist stock lubrication systems for metal forming

Using the SmartFlow® to prime the Uni-Roller® S2

When using a Uni-Roller®, properly priming the rollers is an important start up task. Watch this video to learn how the SmartFlow® walks you through priming rollers.

Testimonial Video - Grant Industries

Customer Grant Industries discusses their Unist Uni-Roller system.

Changing Roller Covers on a Uni-Roller S2

This video shows how to easily remove the Uni-Roller S2's rollers for maintenance.

MF Minute #4

John and Mark discuss the importance of adequate stock lubrication.

MF Minute #3

John and Mark discuss the SPR-2000™ programmable fluid controller.

MF Minute #1

In this Metal Forming Minute, John and Mark provide a basic overview of the Uni-Roller® line of stock lubricators.