Pulse R™ Electronic Control

The Pulse R™ is the ultimate solution for precision control of Unist’s Coolubricator™, Saw Blade Lube™, and Serv-O-Spray™ systems. Choose from several operating modes for a greater range of control and make fine-tuned adjustments with digital display.

Benefits:

- Easy to use adjustment

- Multiple operating modes

- Tamper proof lock

System Integration

Backwards compatible, the Pulse R™ works with new and existing Coolubricator™, Saw Blade Lube™, and Serv-O-Spray™ systems. The Pulse R™ ties into the system control solenoid valve and takes the place of the pneumatic pulse generator timer or logic block. Equipped with fault monitoring and visual feedback of output and input status, you can be confident that your system is working as it should be.

Coolubricator™

When installed on a Coolubricator™, customers enjoy the continuous precision output of the system and can directly read and adjust the pump cycles per minute.

Serv-O-Spray™

When installed on a Serv-O-Spray™, users can configure the Pulse R™ to dispense multiple shots of fluid with one input control signal.

Saw Blade Lube System™

When installed on a Saw Blade Lube System™, customers enjoy the continuous precision output of the system and can directly read and adjust the pump cycles per minute.

Operating Modes

Mode 1: CONSTANT CYCLE ON POWER UP

When powered on, the pumps cycle at the rate displayed (indicated in cycles per minute) until power is disconnected. This is the default mode for Coolubricator™ and Saw Blade Lube System™ applications.

Mode 2: CONSTANT CYCLE ON TRIGGER

When powered on and the input trigger signal is detected, the pumps cycle at the rate displayed (indicated in cycles per minute) until the input is removed.

Mode 3: DELIVER # OF SHOTS ON POWER UP

When powered on, rapidly deliver the selected # of shots. Once power is turned off, repeat function. In Mode 3, the first digit on the display will be flashing “S”. This is the default mode for Serv-O-Spray™ applications.

Mode 4: DELIVER # OF SHOTS ON TRIGGER

When powered on and input trigger signal is detected, rapidly deliver the selected # of shots. Once input trigger signal is removed, repeat function. In Mode 4, the first digit on the display will be flashing “S”.

features an easy to adjust, two-button display.

Specifications

Power supply: 24VDC, 12 watts

Input trigger signal: 24VDC

Output: 24VDC, 10 watts max

Maximum output cycle rate: 250 cycles per minute (modes 1 and 2)

Maximum shots delivered: 99 (modes 3 and 4)

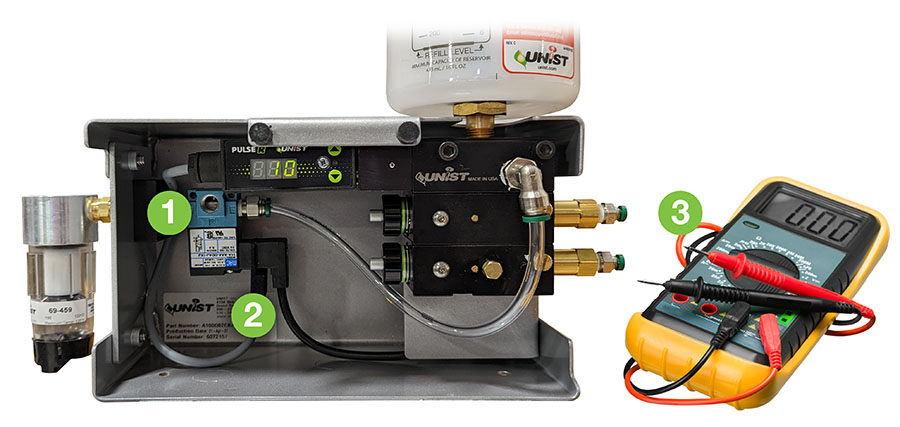

Verifying 24VDC system actuation

24VDC system actuation can be easily verified by any of these 3 methods:

- Solenoid valve label

Check the label on your system valve. - Unist part number decal

Contact Unist with your system part number. - Verify with multimeter

Use a multimeter to verify 24VDC power input. (10% +/- 24vdc)

Ordering information

Order a Pulse R™ digital output timer for an existing system using the part numbers below:

Note: Pulse R™ is only compatible with 24VDC voltage. For new systems, contact Unist to configure the best solution for your application.