- Single-shot precision output

- Reliable Unist pump

- Separate air/fluid control

- Ideal MQL solution - for short-cycle machining

Technical Specifications

| Outputs: |

|

| Pumps(4 types available): |

|

| Actuation: |

|

| Reservoirs: |

|

Options & Accessories

1 signal = 1 shot of lubricant

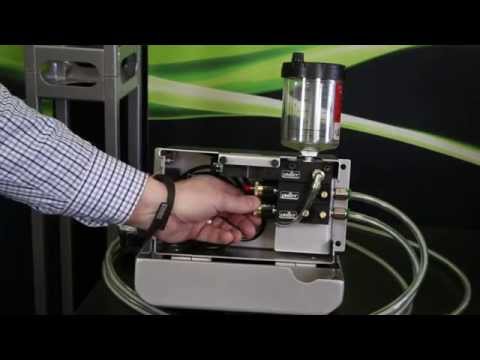

With its precision positive displacement pump and individually adjustable air and fluid volumes, the Serv-O-Spray™ spray lubrication system is the perfect Minimum Quantity Lubrication solution for any operation where controlled, intermittent fluid application is needed.

- Single-shot precision output

- Reliable Unist pump

- Separate air/fluid control

- Ideal MQL solution - for short-cycle machining

- Deliver a fixed amount of fluid with each and every shot

- Adjustable pumps deliver 0.003 - 0.100 mL per stroke.

- Pumps are air actuated

- Easy adjustability and control over spray consistency.

- Neat, clean fluid delivery - Eliminate the mess of flood coolants

- Improves cut quality

- Made for environmentally friendly Coolube®

- Dry chips - higher recycling value

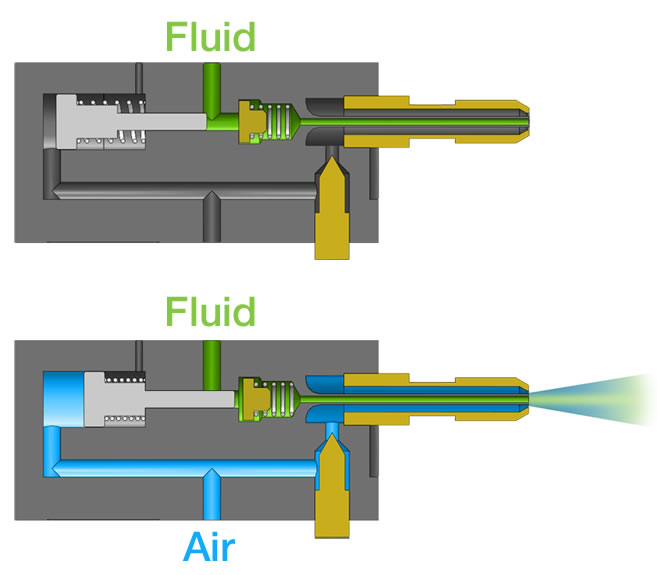

- The Serv-O-Spray™ pump is ready to dispense a shot of fluid.

Note: The system is full of fluid (green) all the way to the nozzle tip

- When an air signal (blue) is applied, the pump piston strokes, immediately pushing a fixed quantity of fluid out the nozzle tip. Simultaneously, an adjustable amount of air surrounds the fluid to break it up and propel it to the point of application.

Actuating your Serv-O-Spray™ spray lubrication system is easy. Every time a compressed air signal is supplied from an actuation valve, the pump will deliver one quick shot of fluid out the nozzle tip along with a controlled amount of air. Air continues to flow from the nozzle tip until the air actuation valve is closed. Each time air is supplied in the spray lubrication system, the pump immediately fires another shot. The pumps can be cycled as often as needed, up to 150 times per minute.

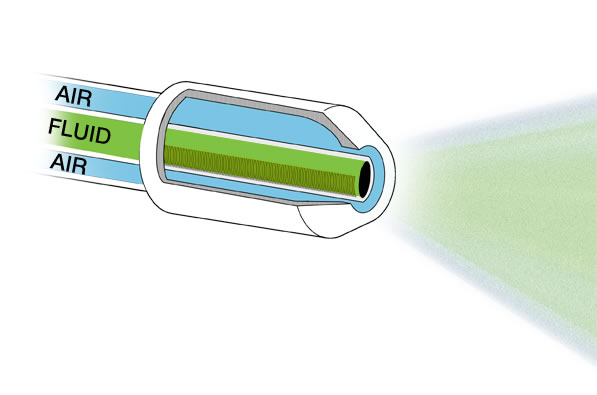

Our Co-Axial nozzles keep the air and fluid separate right up to the spray tip. This unique configuration can deliver fluid over long distances without the need for excessive amounts of air. Each time the pump strokes, a metered amount of fluid sprays out the nozzle tip, and is immediately atomized by the outer jacket of air. This feature on our spray lubrication systems delivers a balanced spray pattern at the point of application.

The Serv-O-Spray™ was designed for precise control over the fluid application with separate fluid and air volume adjustments. This means that finding the sweet spot for your application is a breeze and once it’s set, the Serv-O-Spray™ spray lubrication system will deliver the same amount of fluid again and again.

can be configured for almost any application! Pumps can be actuated independently or in groups to spray multiple points with a single control valve.

- Supplemental and spot lubrication

- Single or multiple spindle drills and taps

- In-die lubrication

How to Install Pulse R™ | Instructions

Step by step instructions how to install a Pulse R™ pump onto your Unist Coolubricator™, Serv-O-Spray™, or Saw Blade Lube System™.

Rebuilding MV Pumps

Learn how to rebuild your MV (Multi-Viscosity) pumps.

Tips & Tricks of Working with Coaxial Tubing

Learn tips for working with coaxial tubing.

Priming A Pump-Based MQL System

In this how-to video, the procedure for priming a pump-based MQL systems is outlined

Working With The Redesigned Capillary Splicer

Learn how to replace nozzles, shorten or replace co-axial hose or retrofit your system to use the improved capillary splicer design.

Testimonial Video - Sigma Machine

Tia Stevenson from Sigma Machine talks about the Quantum™ and Coolube® lubricants.

MQL Minute #9

In this MQL Minute, John and Larry discuss Unist MQL systems with multiple outputs.

MQL Minute #7

Unist multi-viscosity (MV) pumps are discussed in this MQL Minute.

Setting Up Your Coolubricator System

Learn how to do initial setup on a Coolubricator™ system.

MQL Minute #4

In this MQL Minute, John and Larry discuss the differences between Unist Coolubricator™ and Serv-O-Spray™ systems

What is MQL?

An introduction to Minimum Quantity Lubrication (MQL).

MQL Minute #3

John and Larry take a look at some dry chips in the Unist shop.

MQL Minute #1

This MQL Minute provides a general overview of Unist MQL (Minimum Quantity Lubrication) systems.

Installing Coax Nozzles & Splicer Pins

This video demonstrates how to install co-axial nozzles and splicer pins in a Unist MQL system.

Installing a Uni-Max Pump Rebuild Kit

In this how-to video, the installation procedure for a standard Uni-Max Pump rebuild kit is outlined.

Disconnecting & connecting co-axial hose

This video demonstrates the proper procedure for installing and removing co-axial hose from a Unist MQL (Minimum Quantity Lubrication) system.