- Even & consistent fluid application across the entire sheet

- Reduced fluid consumption

- Increased production rates

- Compatible with a wide variety of fluids

Technical Specifications

| Stock type: |

|

| Stock thickness: |

|

| Stock width: |

|

| Fluid type(s): |

|

| Applicator material: |

|

| Fluid supply/capacity: |

|

| Air supply: |

|

| Interface: |

|

| Fluid outputs: |

|

| Control inputs: |

|

| Alarm inputs: |

|

| Outputs: |

|

| Alarm relay: |

|

| Max input rate: |

|

| Programmable ranges: |

|

| Fuses: |

|

| Operating temp. range: |

|

| Storage temp. range: |

|

| Storage: |

|

| Power: |

|

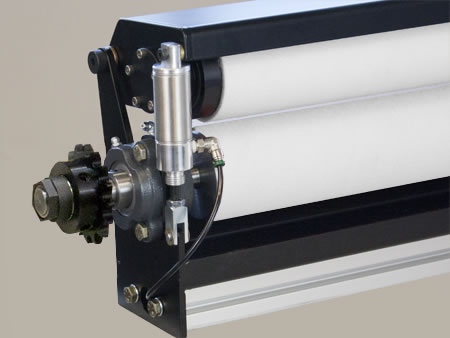

Originally designed for easy integration into Crown multi-die lines, the Unist Sheet Lubrication System™ has found unparalleled success when implemented on various types of sheet fed presses in can end making applications. The amount of fluid applied by the SmartFlow® controller is completely programmable and the patented internally fed rollers provide a consistent coating across each sheet. The rollers are typically slave driven from the sheet feed system so they are synchronized with the rate of the press.

A cleaner press, reduced fluid consumption, and decreased downtime from inadequate lubrication are just some of the benefits of implementing the Unist Sheet Lubrication System.

- Even & consistent fluid application across the entire sheet

- Reduced fluid consumption

- Increased production rates

- Compatible with a wide variety of fluids

The SmartFlow® provides full-featured monitoring of critical parameters such as fluid level, pressure and flow (optional sensors are required) and alerts users with an audible alarm and red LED. An external alarm relay can also be wired directly to a press control.

Typical Unist Sheet Lubrication installations:

MF Minute #5

Learn how to create setups (jobs) in this installment of the Metal Forming Minute