- Protects expensive tooling

- Consistent application at a fraction of the cost of an electrostatic system

- Controlled application of low or no VOC fluids

- Lubricates both sides of stock

- Pneumatic cylinders maintain consistent contact with material

- Reduce fluid usage

Technical Specifications

| Stock type: |

|

| Stock thickness: |

|

| Stock width: |

|

| Line speed: |

|

| Fluid type(s): |

|

| Fluid supply: |

|

| Applicator material: |

|

| Controller: |

|

| Power: |

|

Options & Accessories

more

more

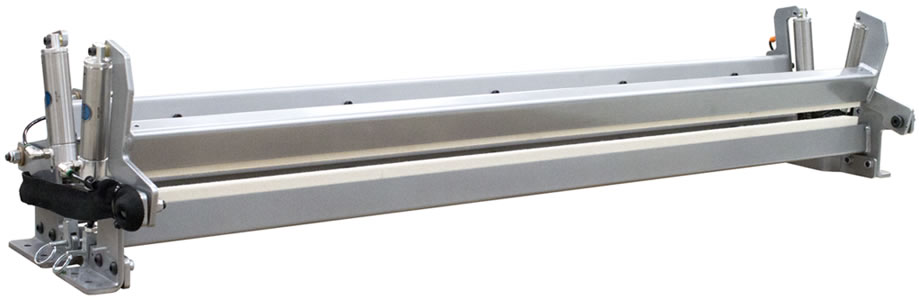

The Unist TSL™ system provides smooth and consistent lubrication to the coil, which helps protect tooling and reduces excess waste. The system features controlled lubricant delivery to both sides of thin stock using specialized felt application pads. The TSL™ is capable of applying lubricant coatings as low as 25 mg/ft² (269 mg/m²), and is an ideal solution for applications where proper lubrication is critical. The Unist TSL™ is commonly used for fin stock and thin coils used in the container and packaging industry.

- Lubricates stock from .002" to .010" (.05mm - .25mm) thick

- Protects expensive tooling

- Lubricates both sides of stock

- Reduces fluid usage

- Protects expensive tooling

- Consistent application at a fraction of the cost of an electrostatic system

- Controlled application of low or no VOC fluids

- Pneumatic cylinders maintain consistent contact with material

- Reduce fluid usage – apply only what you need

- Eliminate the mess of a dip tank lubrication system

Tough, industrial design

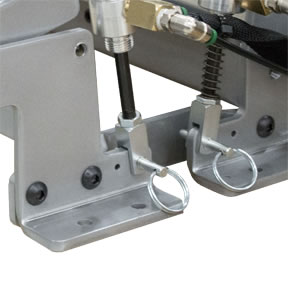

Multiple mounting options

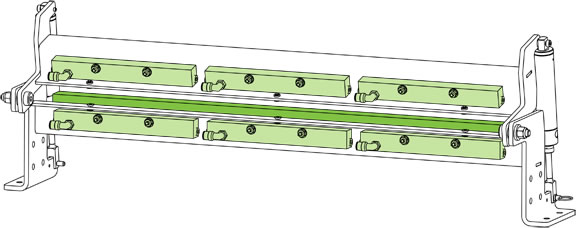

Reversible felt application pads (both sides can be used)

Adjustable pneumatic cylinders

|

9"

(228mm) |

18"

(457mm) |

27"

(686mm) |

|

36"

(914mm) |

45"

(1143mm) |

Lubricant is delivered through separate, modular 9" manifold blocks combined to lubricate multiple widths.

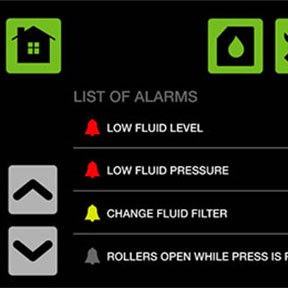

Take control with the SmartFlow®

The SmartFlow® alerts you to issues before they become expensive problems that interrupt or stop your production lines. With the SmartFlow® you'll know immediately if the fluid supply runs low, if fluid pressure varies, or if flow to the applicator is interrupted (Level, pressure, and flow sensors required). The SmartFlow® features an intuitive, easy-to-use interface as well as an access code to prevent unauthorized tampering or changes in fluid settings.

- Monitors critical parameters

- Controls up to 22 outputs

- Stores up to 250 setups

Easy to use touch screen interface.

The SmartFlow® controller can monitor pressure, flow, valve performance and line status.

Job setup wizard makes job creation easy.