Video

What makes Unist unique?An introduction to Unist stamping & metal forming lubrication systems.

Stamping & Metal Forming Lubrication

Unist Uni-Roller® systems bring serious benefits to metal formers in an often overlooked aspect of their process - lubricant application. Metal formers worldwide rely on Uni-Roller® to apply fluid to one or both sides of their coil or blank stock. Uni-Roller's® unique, internally-fed rollers provide such a smooth, consistent coating that fluid waste and messy press areas are things of the past. Not only do Unist customers drastically reduce their housekeeping and cleaning costs, they also save significantly on their fluid costs. Results vary, but we typically see customers saving between 50 and 90 percent on lubricant costs alone. Uni-Roller® lets metal formers rest easy knowing their critical die areas are receiving lubricant. This results in a decrease in scrap and an increase in uptime between die sharpenings and ultimately, an increase in productivity.

Unist Stamping & Metal Forming Lubrication Solutions

Uni-Roller® stock lubricators

Uni-Roller® stock lubricators represent nearly 30 years of partnership with the metal forming industry and are built to provide years of service in tough, industrial environments. Our systems can handle blank or coil stock widths from 1" to over 72", stock thicknesses between 0.005" (0.13 mm) and 0.350" (8.89 mm) and coating speeds up to 150 feet per minute.

The Mini-Roller™ is ideal for thin or narrow stock applications where a Uni-Roller® S2 is too large for the press window. When combined with a SmartFlow™ programmable fluid controller, the Mini-Roller™ will apply the correct amount of fluid for your application and do it consistently day after day.

The Uni-Roller® S2 is the ultimate solution for continuous stock lubrication. Combined with a SmartFlow™ programmable fluid controller, the Uni-Roller® S2 will consistently apply the correct amount of fluid to both the top and bottom of your coil, day after day.

Benefits of Unist Stamping & Metal Forming Lubrication Solutions

- Smooth and consistent lubricant coating

- Coat one or both sides of your coil or blank stock

- Eliminate messy press areas

- Reduce fluid usage by between 50 and 90 percent

- Decrease scrap

- Increase uptime

The Uni-Roller® S2 Powered is the ultimate solution for blank stock lubrication. Combined with a SmartFlow™ programmable fluid controller, the Uni-Roller®S2 Powered will apply the correct amount of fluid for your application and do it consistently from one blank to the next.

Uni-Roller® S2 HG delivers the same smooth and consistent fluid application the industry has come to expect from Unist, and adds an articulating chassis. The upper rollers open a full 6” [152 mm] to avoid deformities in the head or tail of coil stock, making loading easier and preventing damage to the lubricator.

The TSL™ System is a precision lubricator for ultra-thin stock from .002" to .010" (.05mm - .25mm) thick and from 9" - 45" wide (228mm - 1143mm). The TSL™ provides smooth and consistent lubrication to the coil, which helps protect tooling and reduces excess waste. The system features controlled lubricant delivery to both sides of thin stock using specialized felt application pads.

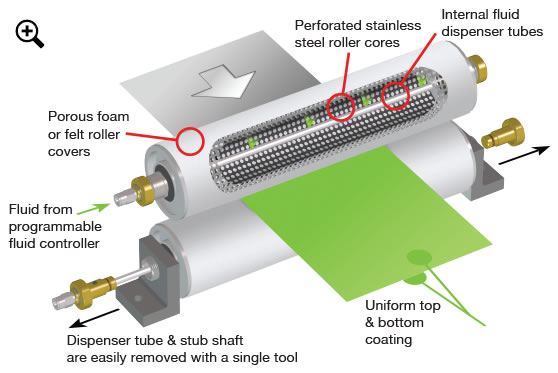

The Internally-fed difference

All Uni-Roller systems feature a unique, internally-fed roller design. This is the key to uniform and efficient fluid application. As illustrated, inside each of the rollers there is a dispenser tube with several small holes spaced along its length. Every time the fluid is injected into the dispenser tubes from the fluid controller, it is dispensed evenly across the inside of the roller through these holes.

The lubricant is then transferred to the stock through a durable polyester felt or polyurethane foam roller cover. These cover materials apply the lubricant smoothly and evenly across both the top and bottom of the stock. As the system continues to cycle, additional lubricant is injected into the rollers to replenish the lubricant applied to the stock. The advantage of this system is consistent application of the exact amount of lubricant required for any particular operation.

Programmable Fluid Controller

The SmartFlow™ programmable fluid controller is designed to precisely control lubricant supplied to Unist Uni-Rollers®, Unist spray nozzles, and in-die lubrication points. The SmartFlow™ allows metal formers to take full control of die and stock lubrication. This full-featured, programmable fluid controller makes configuring, controlling, monitoring, and tracking fluid application easier than ever, leading to increased profits from the stamping or forming operation.

Supplemental or In-die Spray Nozzles

When a continuous coating of fluid is needed on a smooth surface, the Uni-Roller® excels. However, when the surface isn’t smooth, when intermittent coverage is needed, or when additional fluid is needed at specific areas in the die, Unist spray nozzles deliver. Both Airless and Low Volume Spray nozzles are available, each with a variety of spray patterns and mounting options, guaranteeing you can find the right nozzle for your application.

When a continuous coating of fluid is needed on a smooth surface,Uni-Roller® applicators excel. However, when the surface isn’t smooth or intermittent coverage is required, the Unist Low Volume Spray Nozzle is the answer. The Low Volume Spray Nozzle, when paired with the SmartFlow™ programmable fluid controller, delivers a consistent and controlled spray coating to any surface.

The Unist Uni-Roller® S2 excels at applying a continuous even coating of fluid to coil stock or a blank. However, there are times when additional fluid is needed at specific areas in the die. Unist Airless Spray Nozzles provide this extra boost. When connected to the SmartFlow™ programmable fluid controller, they integrate seamlessly into the jobs lubrication profile.

Fluid Supply

A consistent supply of pressurized fluid is required for any system that is controlled by a SmartFlow™ programmable fluid controller. To meet this need, Unist offers a variety of solutions including pressurized tanks from 4 to 30 gallons [15-113 liters], an air-operated diaphragm pump, and a pressure regulator for connection to an existing pressurized fluid supply

A consistent supply of pressurized fluid is required for any system that is controlled by a SmartFlow™ programmable fluid controller. To meet this need, Unist offers a variety of solutions including pressurized tanks from 4 to 30 gallons [15-113 liters], an air-operated diaphragm pump, and a pressure regulator for connection to an existing pressurized fluid supply

The Uni-Blend™ mixing system is designed to accurately mix water with concentrated fluids in any ratio from 1:1 to 50:1 and deliver the mixture under pressure to a customer-supplied piping network. The Uni-Blend™ automatically mixes batches and maintains a reserve supply of up to 50 gallons [190 liters] per ratio. Up to three batches of differing ratios can be maintained in separate tanks.